views

X

Research source

Preparing the Pen Area

Decide how big the pen will be. A 50-foot (15.24 m) enclosure works well for lunging a horse, but if you plan to ride and train your horse in the pen, you may want to build a round pen with a 60-foot (18.28 m) to 80-foot (24.38 m) diameter. The most common round pen size is 60 feet (18.3 m) in diameter. But you can create a pen that is anywhere from 40 to 120 feet (12.2 to 36.6 m) in diameter, depending on how much room you would like for you and your horse.

Find a level, high piece of ground. Look for an area that is not prone to flooding. The footing in the round pen should be firm, with good drainage that does not trap water. If the ground is not level, you can rent a small bulldozer to remove any rocks and level the ground. You can also try to remove any rocks or debris by hand. It’s important that the area is level and smooth so your horse does not get injured when he walks around the pen.

Measure the area. Start at the center of the pen and use measuring tape to create a perfect circle. Be sure to account for the gate in your measurement. The walls or rail fences of the pen should be at least 4 feet (1.2 m) high and have one relatively small gate. The gate should be designed to allow one horse to enter and exit comfortably.

Add soft footing to the area. You can go for a more affordable option of tilling the dirt, or use other materials like sand, wood shavings, shredded rubber, or a combination of materials. To use dirt: Till the soil with a garden tiller, loosening the soil at least 4 inches (10.2 cm) deep. You may have to till the footing often, as dirt compacts with use and can create a hard top layer that can injure your horse’s legs. Keep in mind that in rainy climates, the dirt will turn to mud and you won’t be able to use the pen if it's muddy. To use sand: Start by adding a layer of gravel. Use a shovel or rake to distribute the gravel. Then, spread a layer of sand on top of the gravel, using the rake. Sand provides good drainage and soft footing. For wetter climates, it's a good option. To use wood shavings or mulch: Start by adding a layer of gravel. Then, spread a layer of wood shavings or mulch on the gravel. These materials make good footing because they create a cushion over the ground. But if they go too wet, they can become slick. They also tend to break down easily and turn into dirt over time. To use shredded rubber: Start by adding a layer of gravel. Then, spread a layer of shredded rubber over the gravel. Shredded rubber helps to drain water and provides good footing. But high winds can blow the rubber pieces away in the pen. To use a combination of materials: Start with a coarse layer, like gravel, to help with drainage. Then, add a finer layer of wood shavings or shredded rubber to prevent the top layer from washing away. Add a cushioning layer made of sand to the top to create good footing for your horse.

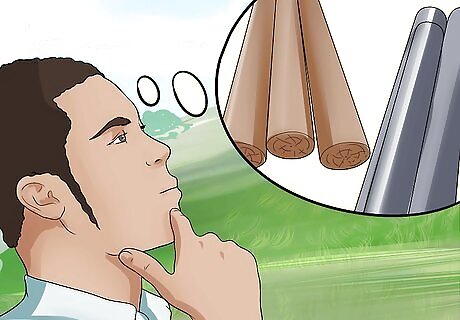

Decide what material you are going to use to construct the pen. When constructing a pen, you have two options for the pen material: Wooden posts and rails: This is likely your cheapest option, depending on lumber costs at your local hardware store or lumberyard. Wooden rails are flexible, in the event your horse falls against them. But they will break under extreme pressure and may cause injury to your horse if they break. The wider the wood rails are, the safer the pen will be. Manufactured steel pipe panels: This option is more costly, but the panels are portable, easy to assemble, and can be adjusted in size as necessary. They are also very durable and can withstand a lot of use. But these panels do not “give” if you or your horse falls into them. Most metal panel manufacturers have changed the corner design of the corral panel from rounded to square to prevent a horse from catching a hoof, neck or halter in the gap.

Using Wooden Posts

Determine how many posts you will need for the pen. The number of posts you need for a given round pen diameter is pi (3.14) times the diameter divided by the distance you want between the posts. Multiplying by 3, instead of 3.14, will give you a rough amount, unless you are making a very large pen. For example, if your pen is 40 feet by 3 feet or has a circumference of 120 feet, and you want 9 feet between each post, divide 120 by 9 to get 13.3. So, you would need 13 posts (with maybe one extra post just in case) for the pen.

Gather your materials. Now that you have an idea of how many posts you will need for your pen, go to your local hardware store and pick up: 7” diameter treated wooden posts (you may need to go to a lumberyard) Pressure treated wooden boards (approximately 150 3/4-inch by 6-inch by 16-foot) Concrete mix (one bag for each post) A 660’ spool of electric braid A gasoline-driven post-hole digger (you can also rent this or dig the holes manually) Nails A hammer

Dig the holes for the gate posts first. Use the post-hole digger to make holes for the gate, based on how wide you want your gate to be. Starting with the gate posts will allow you then work around them as a marker. The holes should be about 2-3 feet deep. Place the gate posts in the holes, perpendicular to the ground. Then, fill the holes with cement.

Dig holes for the other posts. If you have rocky soil, it may be best to have longer intervals between the posts so you have fewer holes to dig. Place the posts in the holes and fill the holes with cement.

Soak the pressure-treated boards in water until they are soft and pliable. Make a solid wall by attaching them to the insides of the posts. Stagger the boards on the posts to distribute the pressure evenly. Cut the remaining boards to the height of your fence and nail them vertically to the inside to cover the joins at the posts. Alternatively, you can create a more open pen by using electric braid instead of wooden boards. Attach 4-5 strands of electric braid between the posts. Depending on how high the posts are, you may use more or fewer strands of braid. Be sure to put enough tension on the braid to prevent sagging between the posts. You may also want to also add a top railing made of wood to the pen to give it a more sturdy appearance.

Install the gate. You will want a gate big enough for a horse to in and out of the pen, but not large enough for a tractor or multiple horses to pass through. Make a gate out of wood or wood and braid. Using the gate posts you built earlier, hang the gate. Attach a latch made out of wood or braid to the gate. You can also purchase ready-made metal or wood gates.

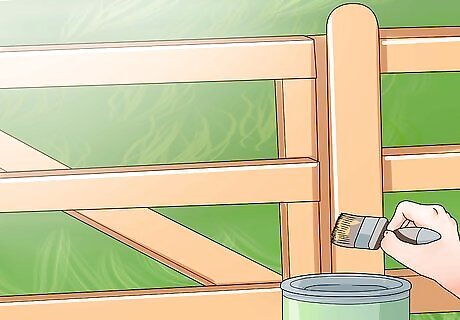

Maintain the wooden pen. If you used pressurized lumber or treated wood posts, they should hold up pretty well. You can also prime, stain, or paint the wood posts and rails to maintain them.

Using Steel Pipe Panels

Determine how many panels you will need. To do this, multiply the diameter of the area by 3.14 to determine the pen’s circumference. Then, divide the circumference by the length of the panels you are going to use. For example: if you plan to use 10-foot panels to construct a 60-foot pen, multiple 60 by 3.14 to get a circumference of 188.4. Then, divide 188.4 by 10 (panel length) to get 18.84. So, you will need 19 panels for a slightly larger than 60-foot pen. If you are going to be adding a separate gate piece, make sure you factor in its length when calculating the overall diameter of the pen.

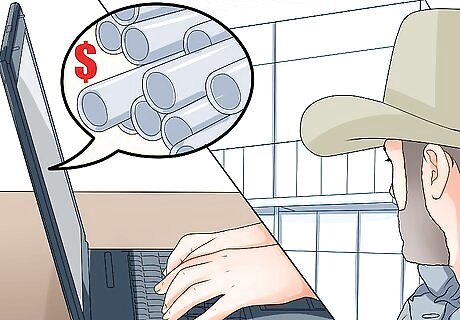

Purchase panels online or at a pet supply store. Look for panels made of high-quality galvanized steel, with a clear coat finish that protects the steel from rusting.

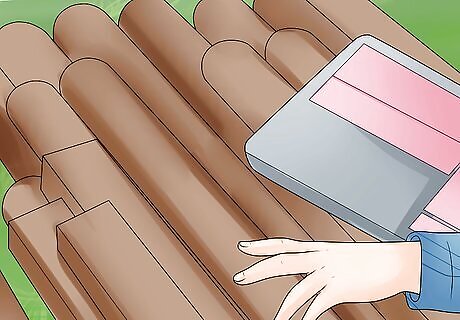

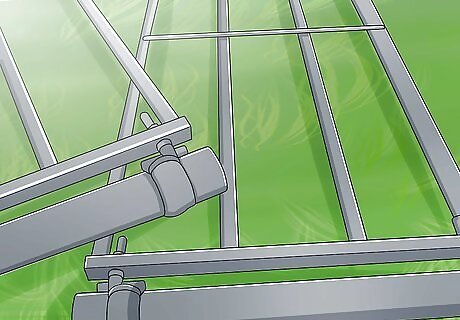

Set up the panels in the pen area. Lay them on their sides so that the inside and outside tabs line up with each other. Some panels have a quick pin latch system with built-in pins. This prevents the pins from getting lost when you move the panels.

Stand two panels up, side by side. Make sure the tabs are overlapping.

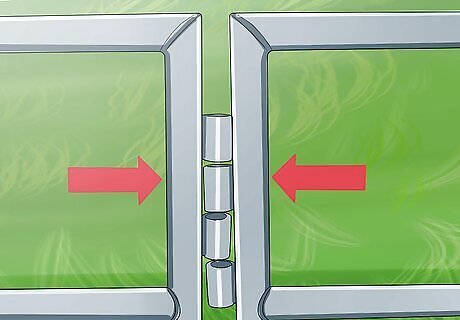

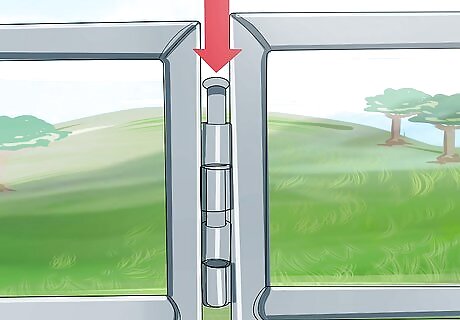

Insert the panel pin between the tabs to connect them together. Continue with the other panels until they have all been mounted. Many panels will be built with mud legs to prevent them from sinking into the ground.

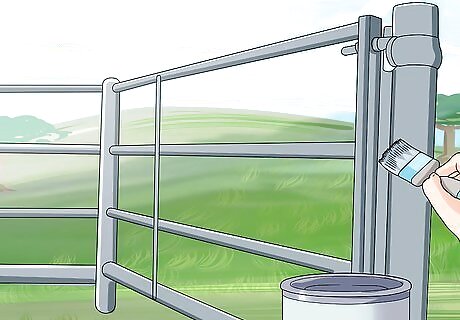

Maintain the steel pen. If the panels are made of high-quality steel with a good coating, they should not fall apart easily. Be wary of rust. If the panels start to rust, paint them with a rust-resistant paint. If the panels get dirty, simply wipe them off with a cloth.

Comments

0 comment