views

Mending a Snapped Fiberglass Rod

Sand or cut the broken ends of the rod so they’re flush. Use 180- or 220-grit sandpaper to smooth the ends so they fit together easily if the rod has a clean break. If your fishing rod has a jagged edge, then use a pair of scissors to cut the sharp edges off of the end of the rod so the pieces are flush. After you make your cut, use sandpaper to smooth out the edges and roughen up the surface. Jagged edges are weaker and are more likely to break again than edges that are flush with one another.

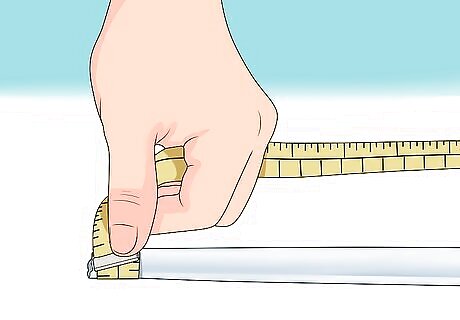

Measure the circumference of the rod. Use a flexible tape measure and wrap it around the broken end of your fishing rod. Then measure the circumference on the other piece of your fishing rod to see if it’s skinnier. Write down your measurements so you know what pole size you need for fixing your rod. You can also measure the diameter of the rod on both of the broken ends if you don’t have a flexible measuring tape.

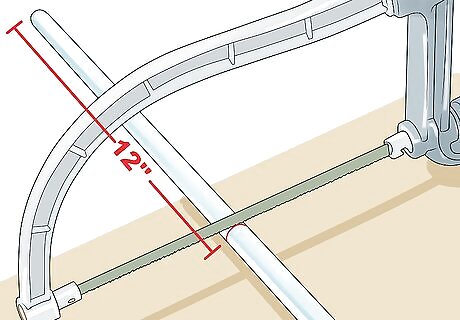

Cut a piece of fiberglass pole so it’s about 12 in (30 cm) long. Get a fiberglass pole that has a circumference that’s about ⁄8–⁄4 inch (0.32–0.64 cm) smaller than your fishing rod. Use a hacksaw to cut out a 12 in (30 cm) section of the pole so it can fit inside your fishing rod and support the rod without breaking. You can buy fiberglass poles from your local hardware store. It doesn’t matter what color you use since it will fit inside of the rod. If your fishing rod isn’t hollow, then using a fiberglass pole won’t work. You can either try to tape your rod back together or get a new one.Tip: You can also cut a section off of an old fishing pole that you don’t use anymore if you don’t have a fiberglass rod.

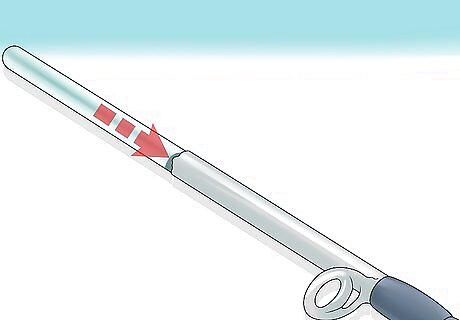

Slide the fiberglass pole into one side of the fishing rod. Hold your rod horizontally so you can position the fiberglass pole in the rod without it sliding too far. Push one end of the fiberglass pole into the end of the rod with the handle. Keep sliding the pole into the fishing rod until there’s 6 inches (15 cm) sticking out from the end. If the pole doesn’t fit snugly inside the fishing rod, then wrap the pole with duct or masking tape to make it thicker.

Apply 2-part epoxy to the exposed side of the fiberglass pole. Open your 2-part epoxy and pour it into a bowl. Use a paintbrush to spread a thin layer of the epoxy on the exposed end of the fiberglass pole. Once the 2-part epoxy is mixed, work quickly so it doesn’t dry or set before you put your rod back together. You can buy 2-part epoxy from any hardware or craft store.

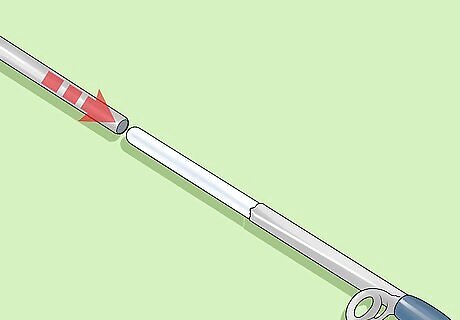

Slide the other part of the rod onto the fiberglass and let it dry. Slowly push the other end of your rod onto the exposed end of the fiberglass pole. Make sure the guides on the pole line up with one another so your line doesn’t get tangled when you try using your pole again. Push the 2 pieces of the rod together so they’re flush. Let the epoxy set overnight so it firmly adheres to the rod. The epoxy doesn’t set right away, so you can still rotate or move the rod pieces once you slide them together. If any epoxy comes out of the joint while you’re sliding the pieces together, wet your finger and smooth out the epoxy so it isn’t as visible. Wrap a layer of electrical tape around the seam if you want an additional layer of security.

Replacing a Rod Guide

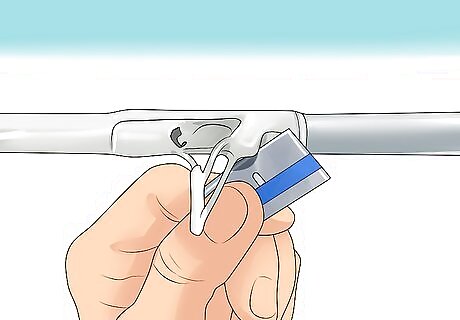

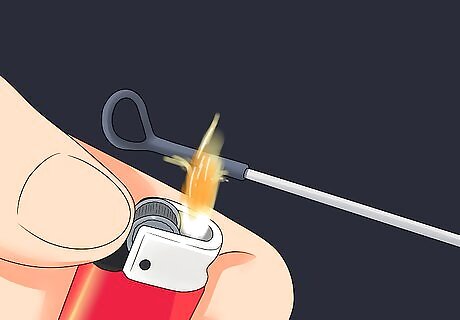

Cut the tape or thread around the broken guide with a razor blade. Use a straight razor blade or a craft knife to remove any threading that may be surrounding the rod guide. If it’s difficult to remove using just a blade, then try heating the area for 3-4 seconds with a lighter to loosen any of the adhesives. Peel off the tape and unwind the threading until the old, broken guide comes off of the rod. Rod guides are the circular metal pieces along the length of the rod that help keep your line straight. Be careful not to heat the rod for too long since it could cause damage to it. Don’t cut into the rod with your razor, or else you could damage it and make it weaker.

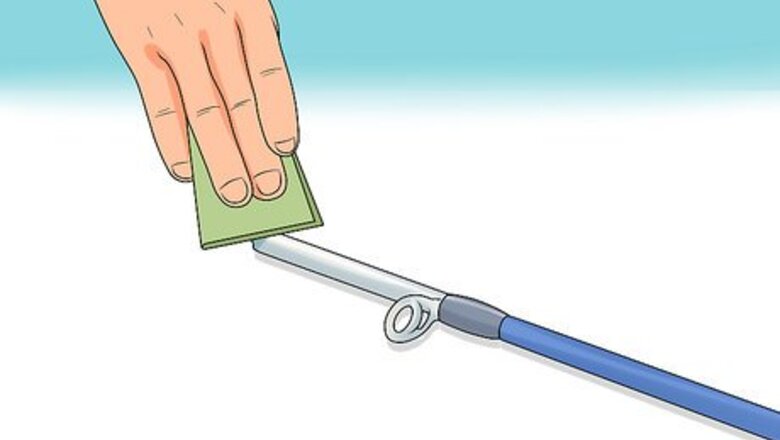

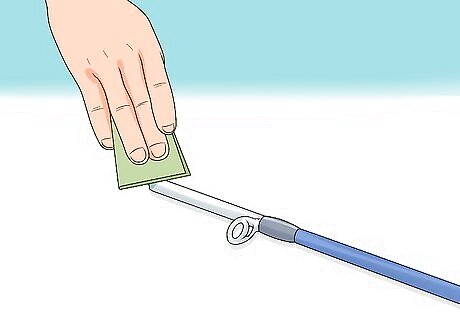

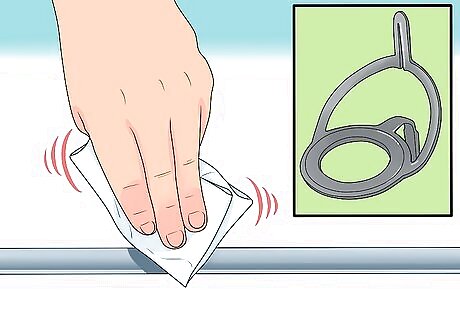

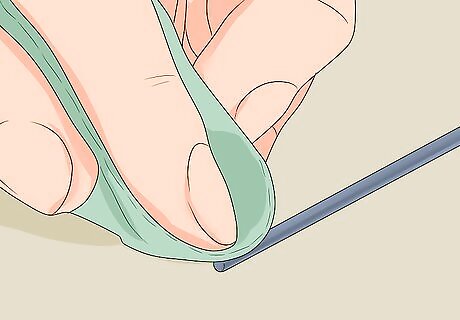

Sand the rod and foot of the new guide to get better adhesion. Use 120- or 220-grit sandpaper to get rid of any leftover adhesive and to add tooth to the rod. Rub all the way around the rod on the spot where you want to place the new guide. Then, use your sandpaper on the foot of the guide, which is the flat part that rests against the fishing rod. You can buy new fishing guides at sporting good stores. Make sure the new guide is the same size and style as the other guides on your fishing rod or else your line may snag or get tangled.

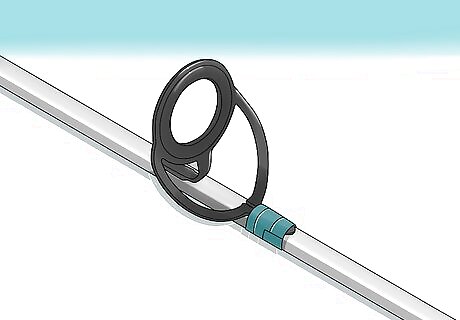

Tape the new guide onto the rod so it’s aligned. Press the foot of the new guide onto the rod so it’s in line with the other guides. Rip off a thin piece of masking tape and wrap it around the foot so it’s held in place. That way, you don’t need to keep holding it in place while you wrap it. You can also use super glue, but it will be difficult to move or readjust once the glue is set.

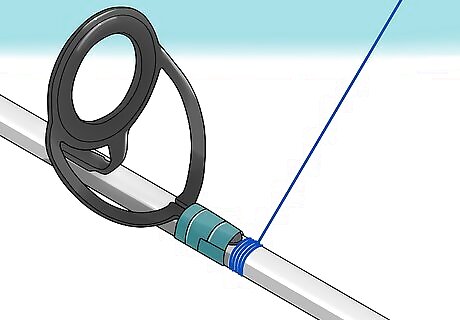

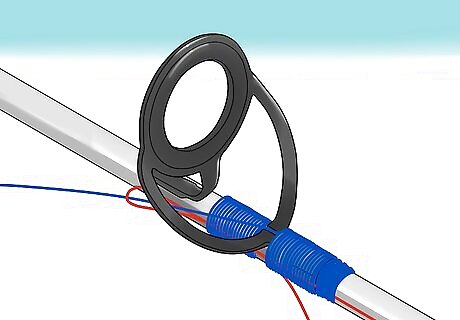

Wrap the foot of the guide with thread to hold it in place. Any type of thread will work for wrapping your guide onto the rod. Loop your threading around the rod so it’s ⁄2–⁄4 inch (1.3–1.9 cm) from the guide’s foot on the side closest to the handle. Maintain tension on the loop and start tightly winding the thread around the rod. Make sure the thread doesn’t overlap with loops you’ve already made and that they are flush with one another. Take the piece of tape off of the foot you’ve wrapped everything below it.Tip: Use a thread that matches the color of your rod if you want it to blend in.

Place a looped piece of thread over the wrap when there’s ⁄8 in (0.32 cm) left. When your wrapping is ⁄8 inch (0.32 cm) from the circular part of the guide, stop winding the thread around the pole. Cut a separate piece of thread so it’s about 6 inches (15 cm) long and fold it in half to form a loop. Lay the second piece of thread on top of your wrapping so the loop sticks out near your guide. If you don’t have any other thread, you can also use a thin fishing line instead.

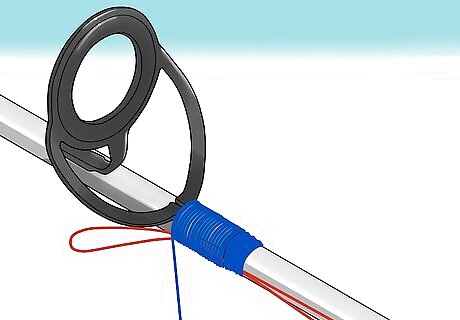

Wrap the final ⁄8 in (0.32 cm) over the second piece of thread. Once the looped piece of thread is on top of the wrapping, continue spinning your thread around the foot of the guide. Continue wrapping the final ⁄8 inch (0.32 cm) of the guide so the middle of the looped piece is held against the rod.

Feed the thread through the looped piece and pull it tight. Once you reach the end of your wrapping, cut the end of the thread you used to wrap and pull it through the middle of the loop. Pull the other end of the looped piece down and away from the guide to pull the thread underneath the wrapping. This way, the wrapping is secured to the rod without having to tie a knot. If you don’t want to use a looped piece of thread, you can also try tying a knot in the threading, but it may not be as strong and it could be more difficult.

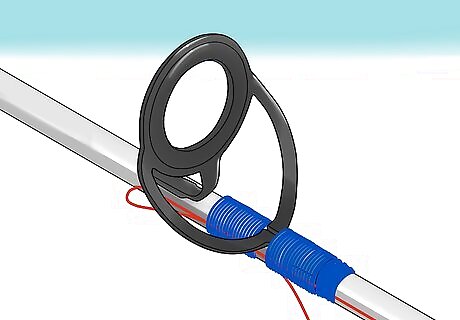

Paint 2-part epoxy onto the thread and let it dry. Mix the 2 parts of the epoxy in a small dish with a paintbrush until they are thoroughly combined. Paint a thin layer of the epoxy over your threading so it hardens and stays in place. Keep the rod horizontal and let it dry overnight before you try using your rod again. Work quickly with the epoxy since it will quickly start to dry and harden once you mix it.

Changing a Rod Tip

Heat the tip top of your fishing rod with a lighter to loosen the adhesive. Set the rod horizontal so you can easily reach the tip. Hold a lighter underneath the tip top of the rod, which is the ringed piece at the end of the rod, and heat it up for 4-5 seconds at a time. Once it’s heated, try pulling it off with a pair of pliers or by hand. If it doesn’t come off easily, try heating it for another few seconds. Heating the tip top helps loosen the adhesive holding it in place so it’s easier to remove. If the tip snapped off of your rod, then you can remove the old tip top from the broken piece or you can skip this step.

Smooth the tip of the rod with sandpaper to remove any shards. Rub the exposed tip of the rod with 120- or 220-grit sandpaper to smooth it out. Rotate the rod around the sandpaper until the tip is smooth and flush. It’s okay if there are small abrasion marks on the rod tip since it will have better adhesion to the new tip top.Tip: If sandpaper isn’t enough to remove the shards on the end of your fishing rod, then carefully cut off the ends with a pair of scissors.

Cut pieces of rod cement into strips that fit inside your new tip top. Rod cement is an adhesive that comes in a solid block and is used for fishing rods to hold guides and tips in place. Use a razor or craft knife to cut out small strips of the rod cement so they fit inside the hollow chamber on your rod tip top. You can buy rod cement and new tip tops from your local sporting goods store or online.

Melt the rod cement inside the tip top with your lighter. Hold the new tip top with a pair of pliers and put the pieces of rod cement in the hollow tube at the end of it. Use your lighter to heat the rod cement for 4-5 seconds and melt it so you can attach it to your rod. Once the rod cement is melted, work quickly so it doesn’t solidify again.

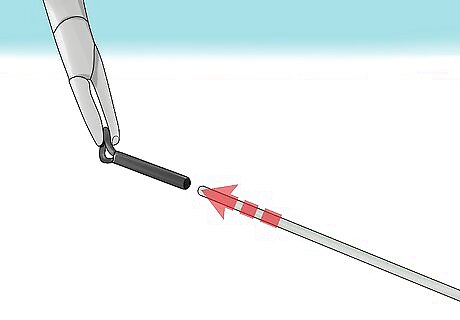

Slide the tip top onto your rod so it lines up with the guides and let it dry. While the cement is still hot, slide it onto the tip of your rod and rotate it so the ring is in line with the other guides. Wipe away any excess rod cement with a piece of paper towel and let it set for at least 1-2 hours. Once the cement is dry, your rod is ready to use! If you need to adjust or reposition the tip top after the cement is dry, then heat it again for 3-4 seconds with your lighter.

Comments

0 comment