views

Wrapping Minor Damage with Electrical Tape

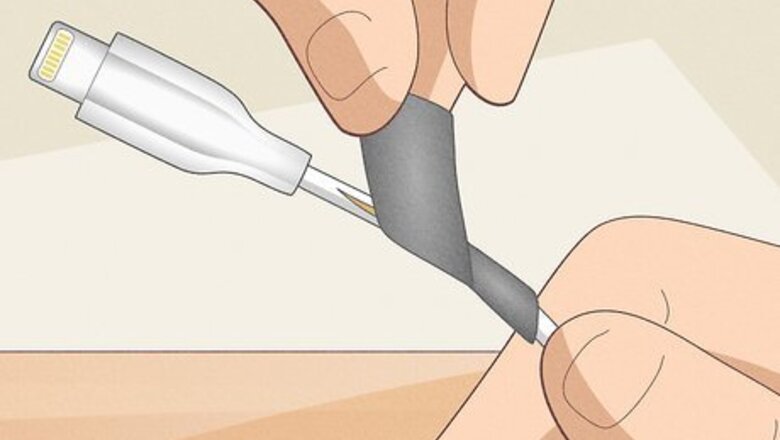

Stick electrical tape over the exposed wire and wrap it around once. Peel up the end of the tape from a roll of electrical tape and center it over the area of the cable with the exposed wire. Press it down on top of the exposed section and wrap it tightly around the damaged area 1 full revolution.Warning: Don’t use duct tape or any other type of tape to cover exposed wire. Electrical tape is insulated and specially made for electrical applications. You can get electrical tape in different colors, so you can try to find a color that most closely matches the cable you want to repair. This method works to repair minor damage in any type of electrical cable. Keep in mind that the electrical tape can get worn out and torn over time, so you might have to replace it eventually with a fresh layer. Examples of cables you could repair with electrical tape are phone or laptop chargers, power cables on electrical appliances, and headphone cords.

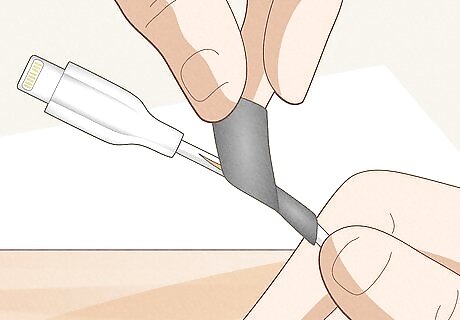

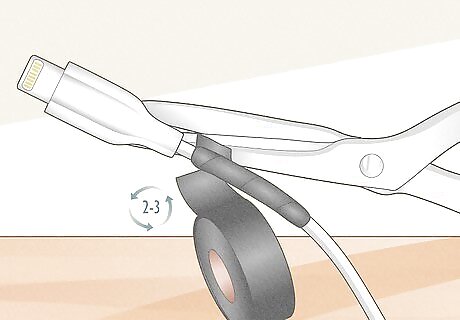

Wrap the tape tightly around the wire 2-3 more times and cut it. Continue to wrap the tape around the damaged area, directly on top of the first revolution you made. Cut or tear the tape when you complete 2-3 more full wraps and stick the end down. Wrapping the tape more than once will help this quick fix last longer and help prevent further damage to the cable.

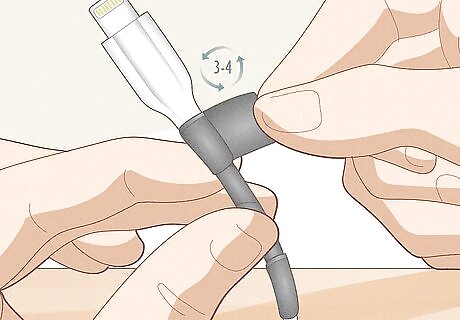

Make 3-4 wraps of tape on either side of the first area you taped. Stick the end of the electrical tape on the cable just to the side of the damaged area you already taped around, overlapping it slightly with the first section of tape. Wrap it around the cable 3-4 times, then cut or tear it. Repeat this for the other side of the first taped area. Covering the undamaged areas of the cable to the side of the area with the exposed wire that you wrapped first will strengthen the cable and help prevent further damage to the area. Rex Cauldwell Rex Cauldwell, Licensed Master Plumber When dealing with exposed wires, safety comes first. Always turn off the power at the breaker before attempting repairs. For minor damage, an electrician may use tape to insulate the wire. However, if the damage is severe, replacing part or all of the wire may be necessary. Working with electricity is dangerous, so it's often best to consult a professional to ensure repairs meet the code.

Repairing Charger Cables with Sugru

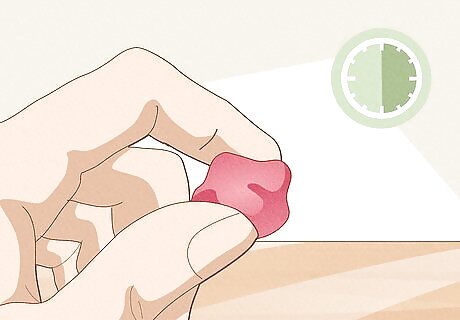

Tear open a packet of Sugru and knead it for about 30 seconds. Rip open a pack of single-use Sugru and pull out the silicone rubber putty. Squish it back and forth between your fingers for about 30 seconds to warm it up and make it more moldable.Warning: Do not use Sugru putty for high-voltage cables or DIY electrical work. Only use this method to fix exposed wires in low-voltage cables like electronic device chargers or headphone cords. Sugru is a type of moldable, adhesive silicone rubber putty that hardens into a rubber-like outer jacket when it cures.

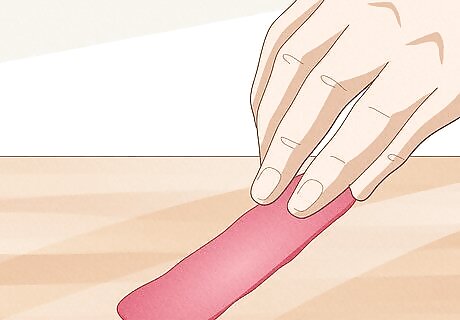

Roll the putty out into a long, thin rectangular shape. Place the putty on a flat surface and roll it back and forth with your fingers until it becomes long and thin. Press it down with your hand until it flattens into more of a rectangle, so you can wrap it around your cable. A piece of Sugru that is about as long as the width of your hand will provide good coverage of the exposed wire and relieve strain on the cable to prevent further damage.

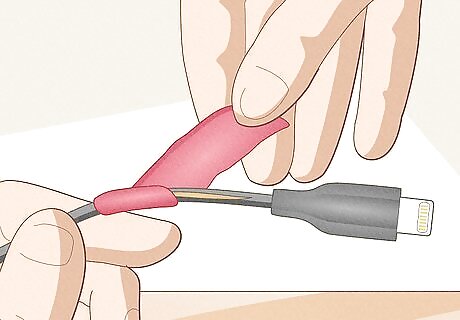

Wrap the Sugru putty around the damaged area and smooth it out. Center the Sugru over the section of cable with the exposed wire and wrap it around the cable tightly. Press the edges of the putty together where they meet and firmly rub the Sugru with your fingertips to smooth out the seam and remove any fingerprints. If the area you’re repairing is close to the wall adapter or power adapter end of the cable, make sure to press the Sugru right up against the power block or the charger plug to create a smooth-looking repair. You can shape it to make it look like a part of the cable.

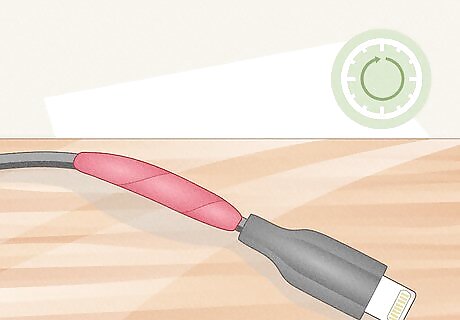

Let the putty cure for 24 hours. Hang the cable up or lay it out on a flat surface somewhere out of the way. Leave it alone for a full 24 hours, so the Sugru has time to cure completely. The putty will turn into a strong, flexible protective casing around the exposed wire. This will prevent further damage to the area.

Applying Heat-Shrink Tubing to Electrical Wires

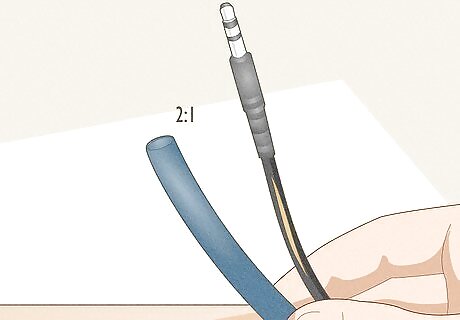

Choose 2:1 ratio heat-shrink tubing with a diameter 2x bigger than your cable. Heat-shrink tubing with a ratio of 2:1 means it will shrink to half its diameter when you heat it up. Heat-shrink tubing that is twice the diameter of your cable and has a 2:1 ratio will shrink to the exact same diameter as your cable to seal and repair the damaged area. Heat-shrink tubing is a type of shrinkable plastic tubing that you can use to cover and insulate wires. You can use a hair dryer or heat gun to heat it up and shrink it. For example, if your cable has a diameter of 1 mm, use 2:1 heat-shrink tubing that is 2 mm in diameter. You can use this method to repair any type of electrical cable with exposed wires. Heat-shrink tubing can be used to repair long sections of exposed electrical wire as well. Examples of cables you can apply heat-shrink tubing to are vehicle wires or home appliance power cords.

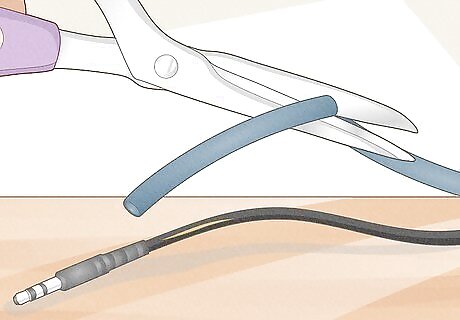

Cut the heat-shrink tubing to at least twice as long as the damaged area. Measure the damaged area and double the measurement. Measure out this length on your heat-shrink tubing and cut the tubing using scissors. The tubing will be about 10-15% shorter after you shrink it, so cutting it twice as long as the damaged area ensures it will cover the exposed wire and some of the cable on either side of the exposed section to prevent further damage.

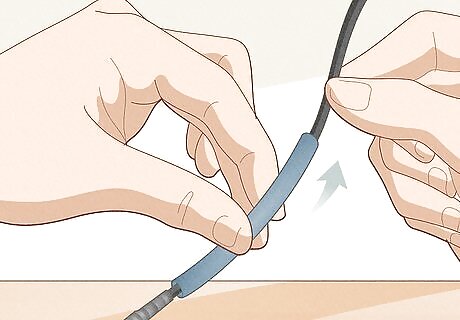

Slide the heat-shrink tubing over the damaged spot. Slip the tubing over the end of the cable and center it over the exposed wire. This will ensure it covers the damaged area and an equal amount of the undamaged cable on either side of it to reinforce the area. Note that heat-shrink tubing won’t work for cables that have ends that are larger than the cable itself, like chargers, because you won’t be able to get the tubing over the large ends. This method works best if the electrical cable has 1 end that is the same diameter as the cable itself.

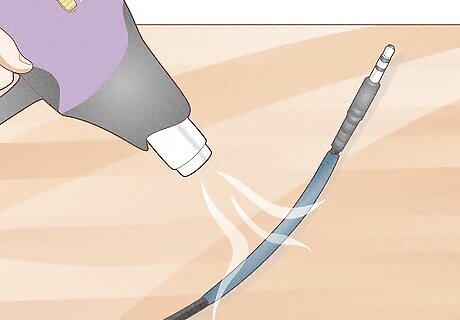

Heat the tubing using a heat gun or hair dryer until it shrinks. Turn a heat gun or a hair dryer on to high heat and hold the tip within about 1 cm (0.39 in) of the tubing. Wave the heat gun or hair dryer back and forth along the entire length of the heat-shrink tubing until it shrinks tightly around the cable. This will stiffen the damaged area and protect the exposed wire to prevent further wear and tear. The tubing will start to shrink almost right away. Depending on how long the section of heat-shrink tubing you are heating up is, you will probably be able to shrink the whole piece in 30 seconds or less. Don’t ever use an open flame to shrink heat-shrink tubing because you can easily just melt it and damage your cable even more.

Comments

0 comment