views

Deciding How to Restore the Bluing

Consider how much of the old bluing has worn away. If most of the original bluing is still in place, you may be able to touch up the bluing yourself with a cold bluing kit. If most of the original bluing has worn away, you may want to consider removing the rest of the old bluing and hot bluing the gun metal.

Consider the age of the gun. Vintage guns dating back to the 19th century were blued using either the rust bluing or fume bluing process. These processes are not used commercially today because of the amount of time involved. There are products commercially available that will let you perform the rust bluing process yourself, or you can find someone who will perform this process for you. Vintage guns that feature silver soldering or brazing cannot be hot-blued, because the caustic salts used in this process will eat the silver. Double-barreled shotguns commonly used this kind of soldering or brazing to keep the barrels aligned properly.

Consider the value of the gun. Hot bluing costs significantly more than cold bluing does, so you need to consider the cost of the re-bluing process you plan to use against what you spent to acquire the gun in the first place and its resale value if you were to sell it. You should also consider the intrinsic value of the gun, or what it means to you, as well as its actual monetary value. If the gun is a family heirloom, you may want to consider spending more money on re-bluing the gun, even if its monetary value is the same that of a gun purchased at a sporting goods store.

Consider the potential cost of the bluing process. In addition to the monetary and intrinsic value of the gun that needs re-bluing, you should also take into account the costs of the bluing process you are considering using. Cold bluing, described in Part Two of this article, is the simplest of the processes, and therefore the cheapest, but it is also the least durable. If you plan to handle the gun a lot after cold bluing it, you can expect the cold bluing to wear off fairly quickly. Hot bluing, described in Part Three of this article, is more durable than cold bluing and lasts longer than either cold bluing or rust bluing, but it requires more work and more equipment to perform. If you feel the gun deserves to be hot blued, but you find the work involved too daunting to do yourself, you may want to hire it done. Rust bluing, described in Part Four of this article, is somewhat less materials-intensive than hot bluing, but more materials-intensive than cold bluing. It is also the most time-intensive of the bluing processes, as you have to let the gun metal rest for a time to achieve the level of coloring you want. Again, you may want to hire someone to rust-blue your gun if you find the process too daunting to do yourself.

Cold Bluing

Remove the old bluing, if desired. Depending on how worn the original bluing is, you may wish to remove it entirely before re-bluing the gun. You can use one of the following chemicals to do so: A phosphoric acid-based automotive rust remover, such as Naval Jelly. White vinegar, which contains acetic acid.

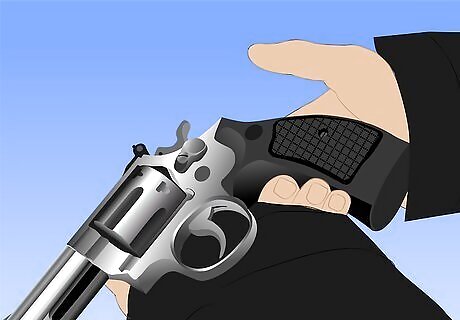

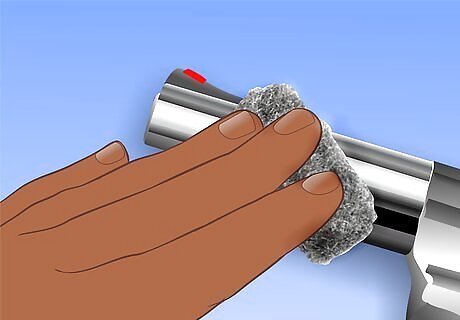

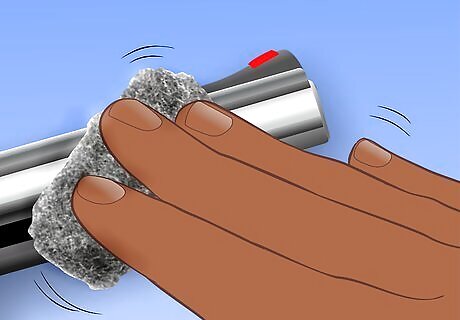

Polish the gun metal. Polishing removes surface rust and any scratches or pitting that the gun may have suffered over the years. You can use either 000 steel wool or 600 to 1200-grit sandpaper for this purpose.

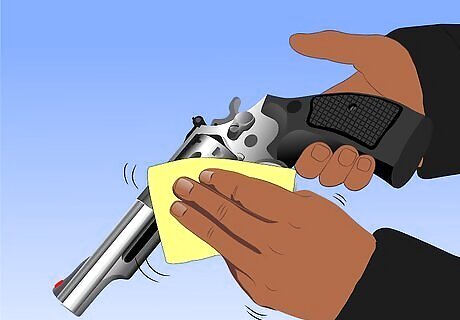

Clean the gun metal. How you choose to clean the metal depends on whether you plan to blue the entire gun or touch up existing bluing. If you plan to blue the entire gun, you may want to immerse the metal in a cleaning solution. Cleaning solutions you can use for this purpose include sodium triphosphate (a commercial detergent), denatured alcohol, or naphtha. (If you choose to use naphtha, you should wash it off with a mild dishwashing detergent and then rinse with hot water.) If you plan to immerse the gun parts to clean them, you can use a wire basket to hold the small parts and thread thin wire through the barrel to lower it into the cleaning solution and raise it again. If you plan to just touch up existing bluing, you can apply a cleaning oil to the places where you want to remove the old bluing, then apply acetone on cotton balls to remove the cleaning oil. (One such cleaning oil, a mixture of vegetable and mineral oils, alcohol, benzyl acetate, and alkaline salts, is sold commercially under the name Ballistol.) As you clean off the old bluing, you may find some scarring that will require sanding or polishing out.

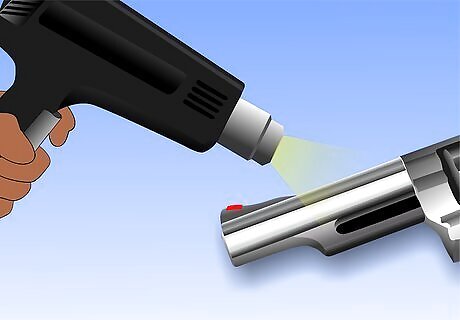

Heat the metal gently. Although this process is called cold bluing, gently heating the gun metal before applying the bluing can help it absorb the bluing better and create a better finish. Heat the metal by leaving it out in the sun for several hours, with a heat gun or blow dryer, or in a conventional oven set to its lowest setting.

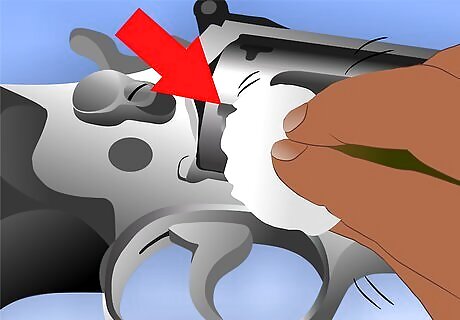

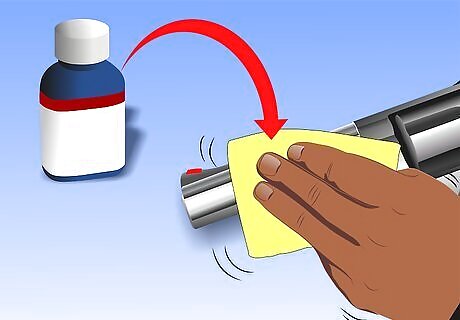

Apply the bluing solution. Slowly apply the solution to the area to be blued as evenly as possible, using a clean applicator. Apply the solution in a single pass to cover small areas, or in sections no larger than 2 to 3 inches (5 to 7.5 cm) when covering large areas, then smooth it out using steel wool. This will prevent the bluing from appearing mottled. For applying the bluing to large areas, old all-cotton T-shirts or new toothbrushes are recommended. For smaller areas, use a cotton ball, cotton swab, or flat toothpick no larger than the area to be covered. You can soak small parts like screws or hard to cover areas in the bluing solution. If you don’t have enough bluing solution to soak a recessed area, put it in a clean spray bottle and spray it liberally on the part over a glass pan or plastic tray. After the part is completely covered, you can pour the solution that landed on the pan or tray instead of the gun metal back into the bottle and reuse it.

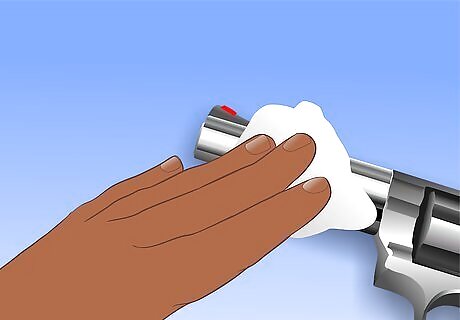

Apply the solution several more times until you have the level of bluing you want. Apply each layer with a fresh applicator, and use a fresh piece of steel wool to smooth out each new layer. The more layers you apply the darker the bluing will be; however, each new layer is progressively less effective than the layer before it. Seven layers should be enough, in most cases, to achieve a dark blue-black finish. If you have spots that won’t darken, start the process over by sanding the spots with 320 to 400-grit sandpaper before applying the solution again. Try to sand no more than the stubborn spots themselves.

Season the finish with gun oil once you have the level of bluing you want. Apply a layer of gun oil every few hours, using a cotton ball to remove the previous layer before applying a new layer. (In essence, you’re washing off the bluing solution with the gun oil instead of with water.) Do not use the cleaning oil for this process, as it will take off the bluing you worked so hard to put on.

Hot Bluing

Polish the gun parts to be blued. Again, you can use either 000 steel wool or 600 to 1200-grit sandpaper to polish the metal.

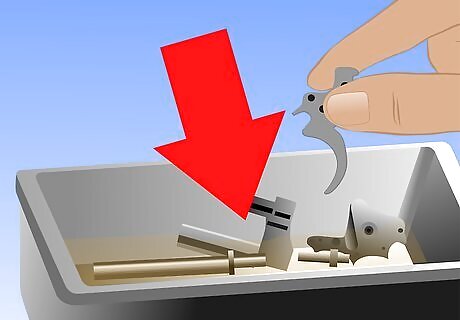

Ready the parts to be dipped in the cleaning and bluing solutions. While the cleaning solution you use may not require it, the chemicals used in the hot bluing process proper, normally potassium nitrate and sodium hydroxide, are highly caustic. You’ll find it easier to dip the gun barrel if you thread soft wire through it and easier to dip the smaller parts if you put them in a wire basket. Rigging the parts now before the cleaning step will make it easier to transfer from the cleaning to the bluing tank, and will also clean the support wire and basket to prevent either from contaminating the gun parts in the bluing tank.

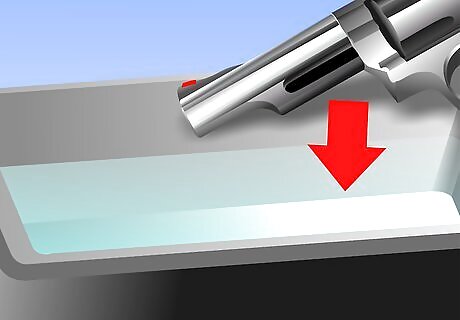

Dip the gun parts in a cleaning solution bath. Parts should be immersed in the bath for 10 to 15 minutes and scrubbed while being immersed to remove any oil, dirt, or grease that could get in the way of the bluing process. You can use any of the chemical cleaners listed in the cleaning step for cold bluing, provided you read and follow all directions for the cleaner’s use, handling, and disposal.

Rinse off the cleaning solution in cold water. Rinsing should take no more than 2 to 3 minutes. If you’ve used dishwashing detergent to remove the cleaning chemical, you may instead need to use hot water to rinse.

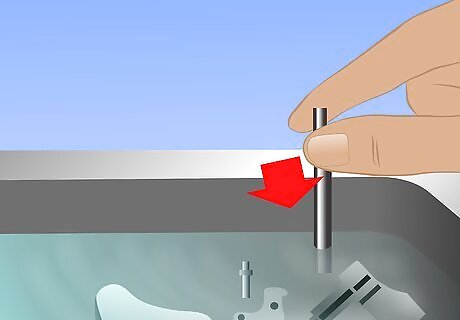

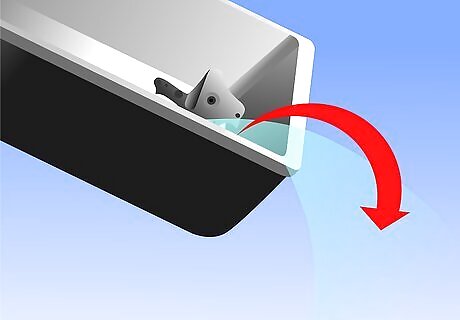

Dip the gun parts in the bluing solution. The hot bluing solution, known as “Traditional Caustic Black.”, must be heated to a temperature of from 275 to 311 degrees F (135 to 155 degrees C). Before heating the bluing solution, stir it thoroughly to break up any salt clumps that may occur on the surface or at the bottom of the tank holding the solution. When dipping gun barrels in bluing solution, dip them at an angle to allow any air bubbles that may form to escape. Be sure to immerse the barrel completely. Swirl the metal basket containing smaller gun parts around in the solution to ensure the parts are completely coated with the bluing solution. Leave the gun parts in the bluing solution from 15 to 30 minutes. Check to see when the metal has reached the desired shade of bluing and remove it from the solution at that time. If your gun has stainless steel parts, those parts are immersed in a different chemical solution, a mixture of nitrates and chromates. It is heated to similar temperatures as the nitrate-hydroxide mixture.

Rinse off the bluing solution in cold water. Swirl the parts through the cold water to help wash away the bluing salts.

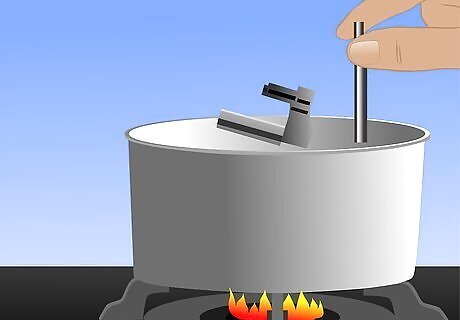

Immerse the gun parts in boiling water. This will boil off any remaining bluing solution residue. Simple parts need to be immersed for 5 to 10 minutes, while complex or ornate parts may need to be immersed for up to 30 minutes. If the gun has any soldered parts, you can apply a chemical to these parts that will color the soldering to match the rest of the metal. Use a cotton swab for this.

Immerse the treated parts in a bath of water-displacing oil. This will protect the finish from rust, sweat, and body oil. Leave the parts in the oil bath for 45 to 60 minutes, until they have cooled.

Rust Bluing

Polish the parts to be blued. Again, steel wool or 600 to 1200-grit sandpaper will work to remove any loose rust, scarring, or pitting from the gun metal.

Clean away any dirt, oil, or grease that remains chemically. You can use any of the cleaners listed in the cleaning step under the cold bluing process, unless the manufacturer of the rust bluing solution you’re using says differently. After you’ve used the cleaning solution, rinse it off.

Coat the gun metal parts with the rust bluing solution. The rust bluing solution is typically a mixture of hydrochloric and nitric acid. This solution actually encourages the metal to rust, but to do so in a uniform manner. Instead of coating the parts with the acid solution, you can instead place an opened container of the acid solution with the gun parts in a cabinet and seal it for a period of 12 hours. The acid evaporates from its container and condenses around the gun metal. This method is called fume bluing. Another variation is to coat the gun metal parts with the rust bluing solution and then put them into a fume cabinet (or, in this case, a damp cabinet) for the same 12 hours. Often, a first layer is applied as a primer before coating the parts a second time and then placing them in the damp cabinet.

Immerse the gun metal parts in boiling distilled water. This stops the rusting process by removing the acid solution.

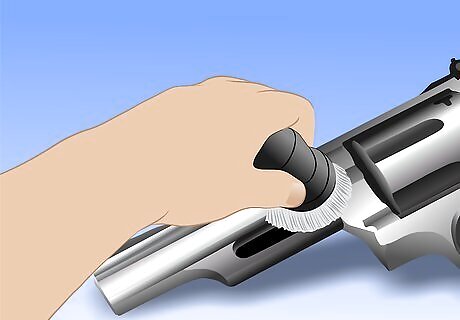

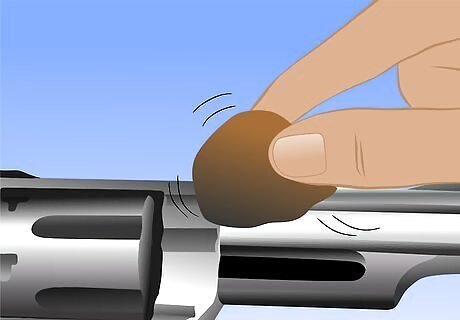

Scrub away the red oxide rust that has formed, leaving the black oxide finish underneath. The surface rust is normally removed with a carding brush or wheel, which features very soft and thin wire bristles.

Repeat the acid treatment, boiling, and scrubbing until you have achieved the desired level of bluing. In some cases, the metal may develop as deep a coloring as it can, making further bluing attempts counterproductive.

Coat the gun parts with oil. The oil inhibits the formation of rust and protects the metal finish from dirt, sweat, body oil, and wear. Once you’ve applied the oil, let the parts stand overnight before assembling.

Comments

0 comment