views

- Repair cracked asphalt shingles with roof sealant. Fully replace broken or missing shingles.

- Slice through blisters in roll roofing to release air and water. Spread roofing cement under the split and cover the split with a patch of roll roofing.

- Split damaged wood shakes with a hammer and chisel. Cut a new shake to fit into the gap and secure it in place with 2 galvanized nails.

- Use roof sealant or cement to seal gaps less than 1⁄4 in (0.64 cm) wide.

Asphalt Shingles

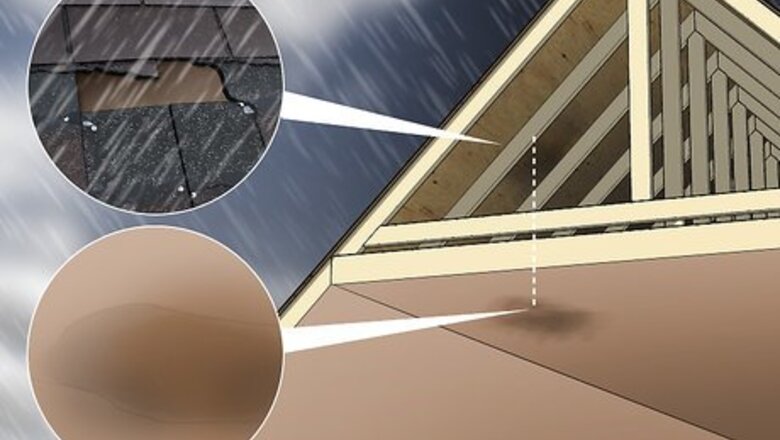

Check for roof damage above water marks on the ceiling. Alternatively, wait until it rains so you can pin point the location of the leak. If you haven’t already tracked down the leak, trace the water damage inside your home. If you have an attic, head up there with a flashlight, and look for water stains or mold. Note the location of any evidence you find, then inspect the corresponding spot on the exterior of your home. If your roof is slanted, inspect areas that are higher than where you’ve found interior evidence of a leak. Water enters the leak then, due to gravity, it gets into the attic at a point farther down the roof’s pitch. If you have trouble, run a hose for 1 to 2 minutes along different sections of the roof. Have a person inside alert you when they spot water.

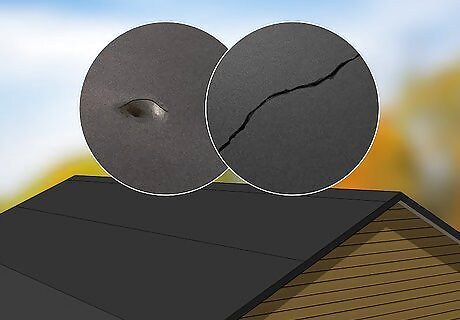

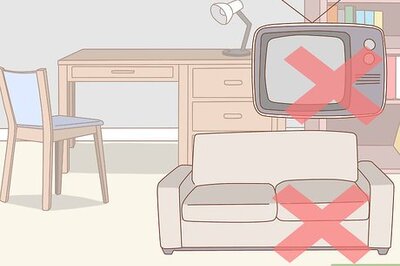

Inspect your roof for widespread wear and tear. Look for curled, cracked, or missing shingles at the leak site, and evaluate your roof’s overall condition. See if there are numerous failing or missing shingles, wide gaps where roofing material meets vents or a chimney, and other signs of widespread wear and tear. Repairing 1 or 2 shingles and resealing minor gaps are relatively easy fixes. However, patches of failing shingles and widespread wear are signs that your roof needs to be replaced, especially if it’s over 20 years old. Additionally, if you find widespread rot or mold on your roof boards or trusses inside your attic, you might have structural issues that require a professional roofer.

Straighten and reattach curled shingles. Over time, the corners of asphalt shingles often begin to curl. Carefully smooth out any curled-back shingles, then use a caulking gun to apply a dab of roof sealant under the raised corners. Press the shingle down, then use a trowel to cover the shingle’s edges with roof cement. Shingles are pliable in warm temperatures. Since they’re brittle in colder weather, you might need to soften a curled shingle with a blow dryer. Don’t use a heat torch or any heat source more intense than a blow dryer, or you’ll damage the shingle.

Repair a clean crack with roof sealant. There’s no need to replace a shingle with a clean tear. Instead, apply a thick bead of roof sealant under the crack with a caulking gun. Press the shingle down, then apply another bead of sealant over the crack. Use a putty knife to spread the top bead over both edges of the crack. To disguise your repair, look around the roof and in the gutter for accumulations of asphalt granules. Collect a small amount, then sprinkle them in the sealant to match its color to your shingles.

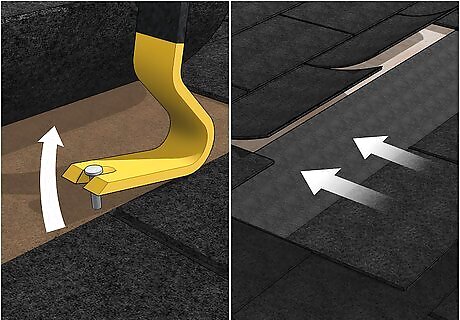

Replace broken or missing shingles. If part or all of a shingle is missing, head to the hardware store to find a matching replacement. To replace a shingle, carefully lift the front edge of the shingle you are replacing and the one above it with a pry bar. Now use your pry bar and insert it way under the shingle you are replacing all the way to the nails holding it down and with a gentle force pry the shingle to loosen the nails, now use the pry bar or hammer to remove the nails, you will also need to remove the nails from the shingles above as the nails will also be holding down the shingle you are replacing, once all nails are out slide shingle out, then scrape the area beneath to remove any leftover roofing cement. If necessary, use a blow dryer to make the surrounding shingles more pliable. After removing the old shingle, use a sharp utility knife to round the back corners of the new shingle; this makes it easier to install. Slide the new shingle into place, gently lift the shingle above, and drive 1 ⁄4 inch (3.2 cm) galvanized roofing nails into the new shingle’s corners.Now replace the nails that you removed from the shingle above. Finally, use a trowel to apply roof cement over the nail heads and edges of the new shingle.

Roll Roofing

Look for cracks or blisters in the roofing material. As you would with a shingle roof, check for damage on the exterior that corresponds with the water stains you’ve seen on the ceiling. Look closely for small cracks around joints, vents, chimneys, or other objects that come through the roof. More obvious signs of leaks include open splits in the roofing material and blisters or bubbles where water and air have collected. You can mend a small gap at a joint, vent, or chimney with roofing sealant. Any gaps wider than ⁄4 in (0.64 cm), open splits, or blistered areas will need to be patched. Like shingle repairs, mending minor damage to asphalt or rubber roll roofing is relatively easy. However, if you notice widespread wear, water stains, mold, or rot on the roof or ceiling, call a professional.

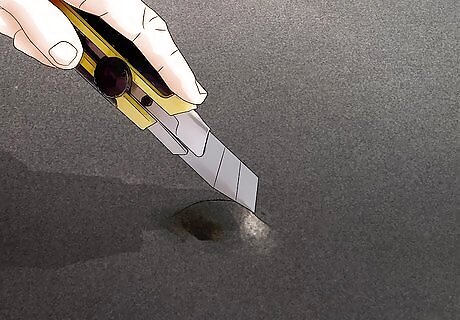

Cut any blisters or bubbles to release air and water. Sweep away any gravel from the damaged area, then carefully slice through the middle of the blister with a utility knife. Cut only through the blister at the top layer of roofing; do not cut the roof substrate, or the fiberboard beneath the rubber or asphalt. If the blister contained water, soak it up with a dry rag. After thoroughly mopping up water, allow it to dry for 12 to 24 hours. If you’re in a rush, dry it out with a blow dryer; just be sure it’s completely dry before you attempt repairs. Blisters often occur with leaks in roll roofing. If there's no blister associated with your leak, skip this step and proceed to mending the tear.

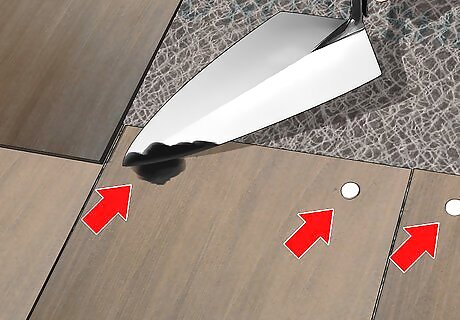

Spread a generous amount of roofing cement under the split. Inspect the fiberboard substrate beneath the tear in the rubber or asphalt. If the substrate is sound, use a small trowel to apply a heavy layer of cement under the edges of the tear. Push the cement as far under the edges as you can without further tearing the roofing material. After cementing the edges of the tear, press it down flat, then drive galvanized roofing nails along each side of mend in 3 in (7.6 cm) intervals. If the fiberboard substrate is unsound, you’ll need to replace the damaged section.

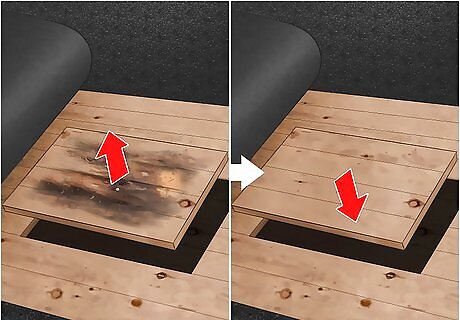

Replace the roofing substrate, if necessary. If you’re dealing with a large, open seam, check the roof substrate beneath the rubber or asphalt for rot or holes. If it’s failing, use a straightedge and sharp utility knife to remove the damaged area. Carefully cut a rectangle-shaped section that contains all of the damaged roofing material. Check for and remove any metal washers and screws that secure the roof substrate to the structure beneath it. Using the section you removed as a template, cut a new piece of substrate from a sheet of high-density fiberboard, which you can purchase at your local hardware store. Set the new substrate into place, then secure it with 1 ⁄2 in (3.8 cm) roofing screws with built-in hex washers.

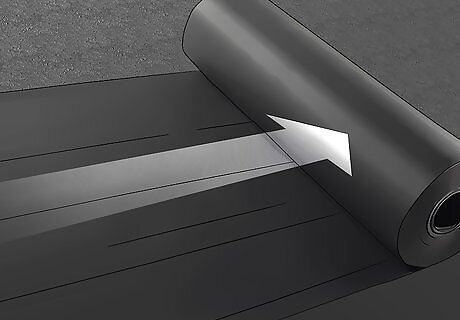

Cover the repaired area with a patch of roll roofing. If you didn’t need to replace the roof substrate, cut a patch of tar paper or rubber roll roofing 12 in (30 cm) wider and longer than the mended section. Apply a generous layer of roof cement over the repaired tear, then set the patch over the cement-covered area. Press it lightly, and drive 1 ⁄4 in (3.2 cm) galvanized roofing nails around the patch’s edges in 3 in (7.6 cm) intervals. If you did replace the substrate, add layers of rubber roll roofing until the area is flush with the surrounding roofing material. Cut a piece of tar paper or rubber roll roofing 12 in (30 cm) wider and longer than the repair area, apply a generous layer of cement, then set the patch over the cement-covered mend. After setting the patch in place, press it lightly and drive roofing nails around its perimeter. Ensure the nails that secure the patch don’t overlap with any hardware you've used to hold the fiberboard substrate in place.

Add a final layer of roofing cement for a watertight patch. After covering the mend with the patch, use your trowel to apply a heavy layer of roofing cement over the entire repaired area. Spread the cement over the patch’s perimeter, and be sure to cover the nail heads. Use a putty knife to feather the cement past the patch’s edges, and try to make a smooth surface that won’t collect water. If your roll roofing is asphalt, spread a layer of asphalt gravel over the cement while it’s still wet. This will help protect the roofing material.

Wood Shakes

Inspect your roof for signs of damage. If you haven’t already tracked down the leak, follow the same steps as you would for any other roofing material. Look for roof damage on exterior areas that correspond with signs of a leak inside your home. Keep an eye out for broken shakes, gaps in flashing, and other signs of wear and tear. Shakes are basically shingles made out of wood instead of asphalt. If you have slate shingles, you’ll need to split them and saw off the nails as you would a wooden shake. Remember that replacing a shingle or shake here and there is relatively simple, but widespread wear and tear calls for a professional.

Split damaged shakes with a hammer and chisel. Carefully position the chisel into the damaged shake, then strike the chisel with a hammer. Use a steady, controlled motion to avoid damaging adjacent shakes. After splitting the damaged shake, remove the pieces with a set of pliers.

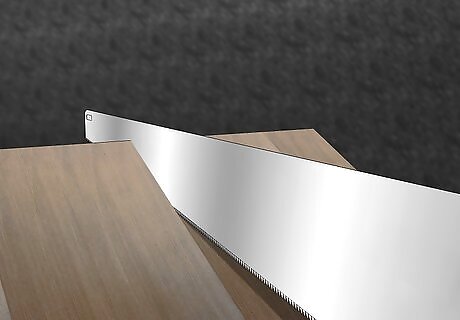

Use a hacksaw to cut off the nails that secured the broken shake. Peer into the spot where the broken shingle sat, and locate the nails that secured it. Slide the hacksaw blade beneath the shingle above the one you’ve removed. Saw through the old nails where they protrude from the roof board to make room for the new shingle. Be careful when using a hacksaw or any other sharp tools. If you’re not confident in your ability to wield saws, hammers, or other tools on a pitched surface, call in a professional.

Cut a new shake to fit into the gap. Purchase a shake that matches those on your roof online or at your local hardware store. Measure the width of the space where the old shake sat, and use a utility knife or fine-toothed saw to trim the new shake so it’ll fit into the gap. Trim the new shake about ⁄8 in (0.95 cm) less than the gap’s width so it’ll have room to expand.

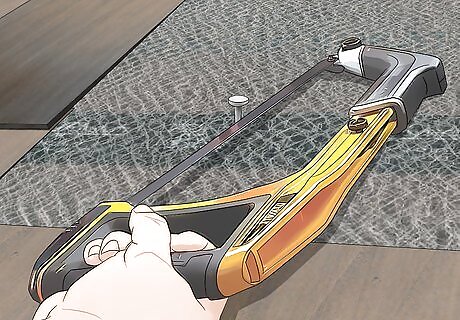

Slide in the new shake, and secure it with 2 galvanized nails. First, slip the new shake under the one above the gap, and tap it to within 1 in (2.5 cm) of its final position (it should stick out a bit). Hammer 2 galvanized wood shingle nails into the new shake at an upward angle just below the edge of the shake above it. Next, place a wood block against the new shake, and strike the block with a hammer to tap the shake into place. As the shake slides the last 1 in (2.5 cm) into place, it’ll pull the nail heads beneath the shake above it. If you’re unable to use this technique to secure the nails inconspicuously, just drive the nails in directly below the shake above the replacement.

Seal any exposed nail heads with roofing cement. If the nail heads aren’t completely covered by the shake above the replacement, apply dabs of cement over each head. Then smooth the cement surface with a putty knife or small trowel. If your shakes or shingles are bonded by sealant and you broke the seal when you removed the old piece, apply a bead of roof sealant or cement around the edges of the replacement shake.

Leaky Joints

Inspect areas where surfaces join, such as at a chimney or valley. Look for gaps in caulk, sealant, or aluminum flashing where any objects intersect with or emerge from the roof. These are some of the most common sources of roof leaks, and smaller gaps are easy to repair. Small gaps can be treated with caulk or roof sealant, but larger cracks or tears require patching or new flashing.

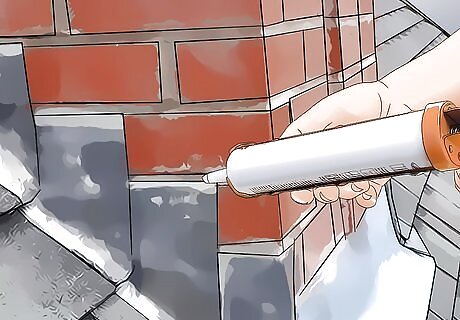

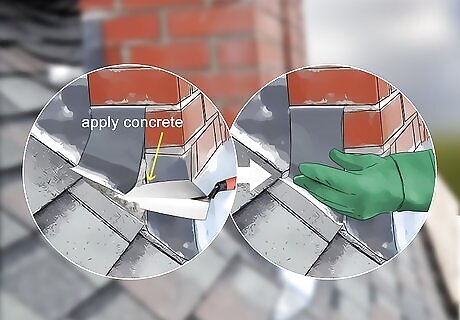

Apply roof sealant or cement to gaps less than ⁄4 in (0.64 cm) wide. Scrape away old sealant, wipe away debris, and dry the area thoroughly before applying a new compound. Use a thin, flexible putty knife to apply roof cement to small cracks in the sealant around chimneys, pipes, or other joined surfaces. For small gaps at the metal or rubber collar of an exposed pipe or vent, apply a bead of waterproof silicone-based caulk with a caulking gun. Gaps larger than ⁄4 in (0.64 cm) will require a more substantial fix instead of a simple sealant.

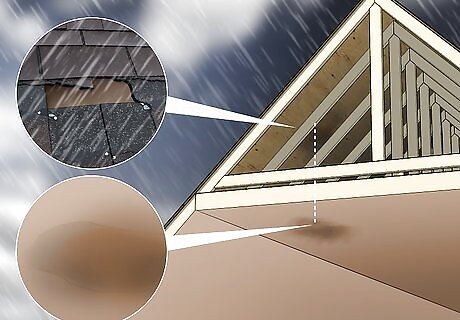

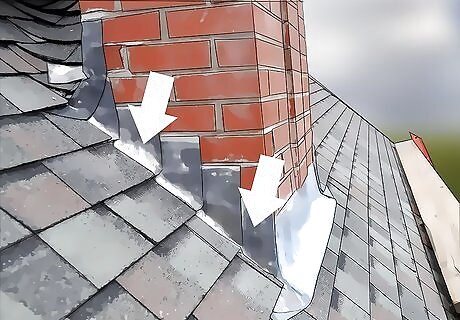

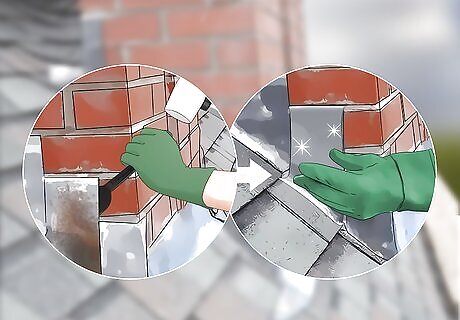

Repair rusted or loose flashing at a joint. Flashing is typically made of steel or aluminum, and it seals joints around chimneys, valleys, siding, and walls that intersect the roof. If you find loose flashing, apply a bead of roof cement beneath it, then press it back into place. If a small area of flashing is rusted, slide a new piece of galvanized steel flashing beneath the failing area, then seal it with roofing cement. If you’re any shingles adjacent to flashing are loose, avoid nailing the shingles on the side that makes contact with the flashing. Instead, bond the shingles to the flashing using roof cement to avoid puncturing the flashing.

Replace large areas of failing flashing, if necessary. Pry off stretches of unsound flashing and old roof cement with a chisel or pry bar. Measure your chimney, vent, or other joined area, and use a pair of straight cutting tin snips to cut a section of pre-bent base flashing to fit the joint. Your flashing should overlap the joint by about 4 in (10 cm) on each side. Apply strips of ice-and-water barrier to the joint before installing the flashing. For a chimney or other object protruding from the roof, apply strips 4 in (10 cm) up the object’s height. Wrap the flashing around the joint and seal it with roofing cement or caulk. If there are nail holes on the flashing’s edge, drive galvanized roofing nails into them. If you have a shingled roof, you might have needed to remove shingles in order to access the old flashing. Replace them, if necessary, and secure them to the flashing with roofing cement. Properly replacing all of the flashing around a chimney is complex and may require custom-made materials. If necessary, consult a professional.

Comments

0 comment