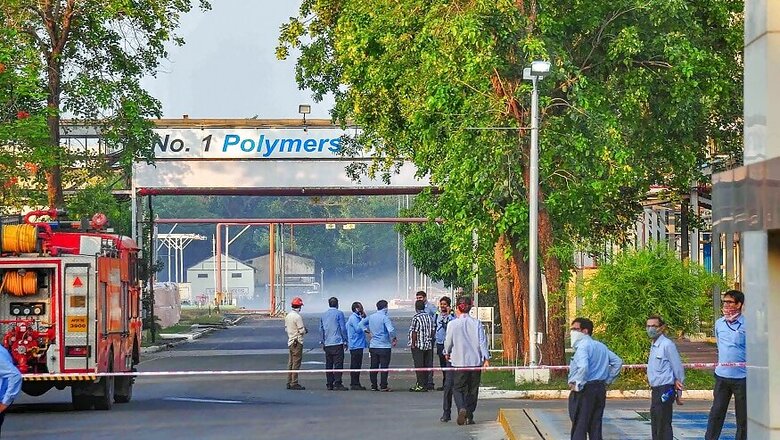

Vizag Gas Leak: Lack of Green Clearance from Centre Indirect Cause of Tragedy, Says State Govt Panel

views

The operations and multiple expansions of the manufacturing unit of LG Polymers Pvt Ltd in Vizag without a valid environmental clearance was not merely a procedural lapse and may have indirectly led to the gas leak resulting in harm to humans and environment, the high-power committee of the Andhra Pradesh government has said in its report.

The committee was mandated with probing the causes behind the accident and was also asked to submit measures to improve safety of industrial units. Twelve people died and 585 people fell sick following a Styrene gas leak that occurred from the industry on May 7.

On Tuesday night, the local police arrested the CEO of LG Polymers, its two directors, besides nine other company officials in connection with the May 7 incident.

The state pollution control board also suspended three of its officials for "gross negligence". On Wednesday, the Visakhapatnam district magistrate sent 12 accused in the case to police remand till July 22.

The committee, while examining the environmental permissions granted for the industry, noted flaws in the decisions of the Andhra Pradesh Pollution Control Board (APPCB) and lacunae in the environmental regulatory process, at both the state and central level.

The committee fund that if LG Polymers had applied for environmental clearances under the Environment Impact Notification (EIA), 2006, the project scrutiny built-in for vetting such projects could have addressed the possibility of gas leaks and other hazards.

However, even in its April 2018 application submitted to the Centre seeking a green clearance, the company did not inform about the actual or perceived risks to the human health, the committee noted.

News18 had reported on May 9 how LG Polymers had expanded its operations six times between 2004 and 2018 only on the basis of APPCB permissions and that it had not obtained an environmental clearance under EIA notification, 2006.

'APPCB Should Have Consulted Union Environment Ministry'

During the examination of environmental permissions, the committee said the APPCB granted ‘consent to operate’ and ‘consent for establishment’ permissions for their expansion and unit modifications without pressing them to seek a clearance from the Centre.

The APPCB told the state committee these permissions, under the Air Act and Water Act, were given as they are not linked to environmental clearance.

The state committee, however, said legal experts should examine this issue. If it is held that environmental clearance is needed before APPCB permissions, then the approvals granted for expansion 2010 onward would have to be examined too.

The committee said that at least the APPCB should have addressed this issue to the Union environment ministry while approving the expansions of LG Polymers unit. The pollution control body did not do so between 2010 and 2014.

In its suggestions, the committee said that while granting permissions under Air Act and Water Act, the APPCB ought to take into account the residential areas located in the vicinity of red-category industries.

“It should be made a mandatory practice that if the Consent for Establishment has been accorded for a Red category industry or hazardous industry or an industry dealing with explosive substances, a buffer zone around the industry should also be demarcated and shared with the concerned local bodies,” the committee said in its report.

“These areas should be strictly marked as prohibited for residential areas or any other type of habitations. It is always preferable that these areas are within the factory premises but earmarked as a buffer zone,” the committee added.

Reasons for Leak

Upon examination, the committee found the Styrene gas leaked from storage tanks due to high increase in its temperatures.

The rise in temperatures led to polymerisation and the heat generated due to this led to runaway reactions.

“Increase in temperature to the boiling point of Styrene monomer viz. 145°C led to the boiling of the liquid Styrene, leading to uncontrolled vapour formation. Further increase in temperature led to increase in the pressure of the vapour which led to the uncontrolled release of vapour from the vents into the atmosphere,” the committee said.

Comments

0 comment