views

X

Research source

Calculating and Marking the Bend Points

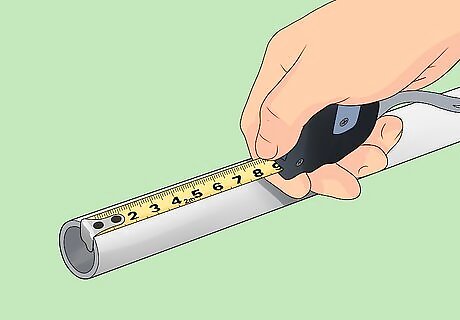

Measure the actual obstruction height with a tape measure. Use a tape measure to determine how far the obstruction – which may be another piece of pipe or conduit – juts out from the wall or floor. Write down the actual obstruction height onto a piece of paper. Even if you know the gauge or thickness of the obstructing pipe, don’t rely on this for your calculations. Instead, use the tape measure to get the exact measurement, from the wall to the widest outside edge of the obstruction. For instance, your obstruction might be a 2 in (5.1 cm) gauge PVC pipe which actually has an outside diameter of 2 ⁄8 in (6.0 cm). This second number is your actual obstruction height.

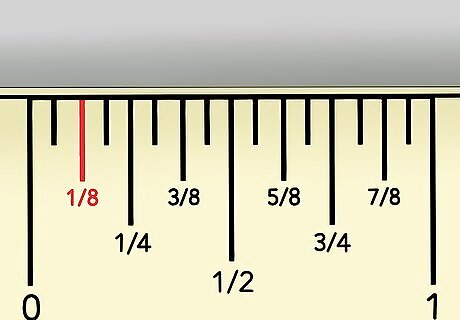

Add at least ⁄8 in (0.32 cm) to reach the adjusted obstruction height. To make sure you leave a small amount of clearance above the obstruction, factor this clearance into the obstruction measurement. To do this, either round the actual obstruction height up to the nearest half inch, or add at least ⁄8 in (0.32 cm) to the actual obstruction height. Write this new number down as the adjusted obstruction height. For the PVC pipe, you could choose either 2 ⁄2 in (6.4 cm) or 3 in (7.6 cm) as your adjusted obstruction height. The latter will leave you with more clearance.

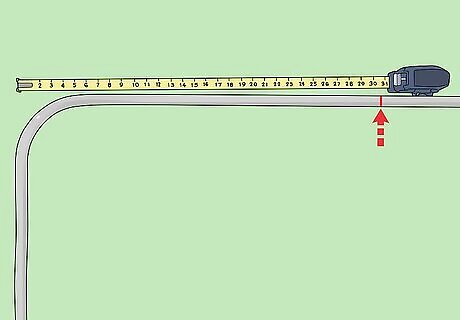

Find the distance between the obstruction and the previous piece of conduit. Place the end of your tape measure in line with the end of the previous piece of conduit or the coupling where you’ll be attaching the end your bent conduit. Extend the tape measure over to the center point of the obstruction. Write this measurement down as the actual distance. For instance, there might be 30 in (76 cm) from the coupling to the center point of the PVC pipe obstruction.

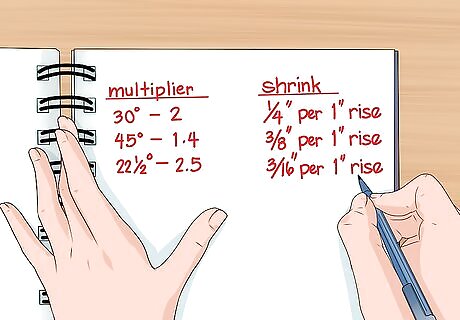

Calculate the amount of shrink based on the adjusted obstruction height. The overall length of the conduit will be ⁄16 in (0.48 cm) shorter per 1 in (2.5 cm) of the adjusted obstruction height. Multiply the adjusted obstruction height by ⁄16 in (0.48 cm) to find the shrink amount. Use the following examples as guidance. If your adjusted obstruction height is: 1 in (2.5 cm), the shrink amount is ⁄16 in (0.48 cm). 2 in (5.1 cm), the shrink amount is ⁄8 in (0.95 cm). 3 in (7.6 cm), the shrink amount is ⁄16 in (1.4 cm). 4 in (10 cm), the shrink amount is ⁄4 in (1.9 cm). 5 in (13 cm), the shrink amount is ⁄16 in (2.4 cm). 6 in (15 cm), the shrink amount is 1 ⁄8 in (2.9 cm).

Add the shrink amount to the distance to determine where the center bend should go. The most common type of 3-point saddle bends consists of a 45-degree bend in the center and a 22.5-degree bend on either side. To determine where to place the center bend along the conduit, add the shrink amount and distance measurement together. Write the number down as your center line measurement. If your actual distance between the end of the coupling piece and the center of the obstruction is 30 in (76 cm), and you calculated a shrink amount of ⁄16 in (1.4 cm), your center line measurement is 30 ⁄16 in (77.6 cm). While these are the most common angles to use, you can create a center bend of 60 degrees and 2 outer bends at 30 degrees each. This would result in a saddle bend with a deeper angle but a shorter overall footprint. Use the same calculations when making the marks on the conduit.

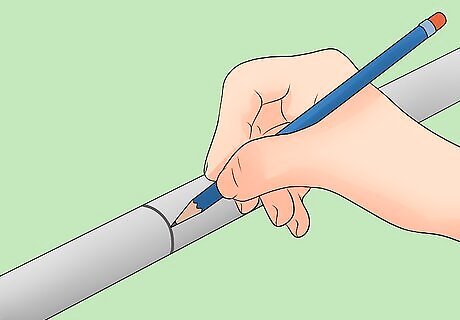

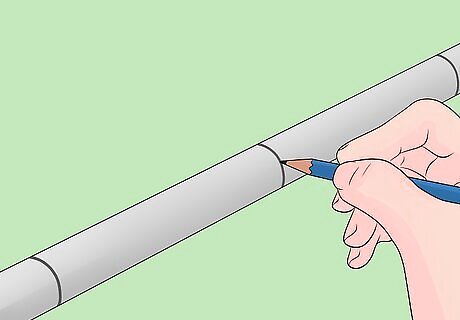

Use a pencil to draw the center line in a ring around the conduit. Use the center line measurement you just calculated to mark the center line at the correct distance away from one end of the piece of conduit. Extend the line all the way around the perimeter of the conduit so you can see it from all sides. Draw it on in pencil so that you can easily erase it later. If your center line measurement is 30 ⁄16 in (77.6 cm), mark the center line 30 ⁄16 in (77.6 cm) in from the end.

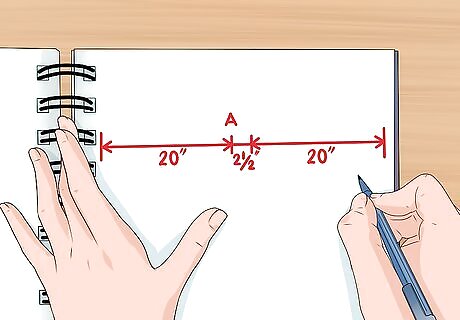

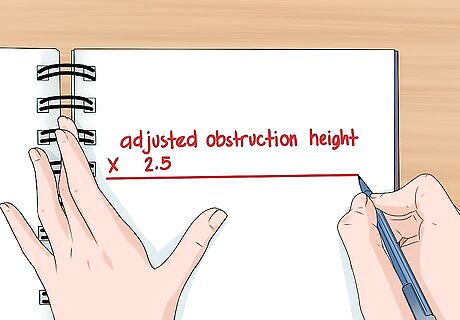

Multiply the adjusted obstruction height by 2.5 for the placement of the outside bends. To determine how far out each outside bend mark should be from the center line, take the adjusted obstruction height and multiply it by 2.5. The 2 outside lines will be the same distance from the center line, with 1 on the left and 1 on the right. Jot this number down as the outside line measurement. Use the following examples as benchmarks. If your adjusted obstruction height is: 1 in (2.5 cm), place each outside line 2 ⁄2 in (6.4 cm) from the center line. 2 in (5.1 cm), place each outside line 5 in (13 cm) from the center line. 3 in (7.6 cm), place each outside line 7 ⁄2 in (19 cm) from the center line. 4 in (10 cm), place each outside line 10 in (25 cm) from the center line. 5 in (13 cm), place each outside line 12 ⁄2 in (32 cm) from the center line. 6 in (15 cm), place each outside line 15 in (38 cm) from the center line.

Mark the 2 outside lines onto the conduit with a pencil. Hold the end of a tape measure at the center bend line. Extend it out to the right side, using the outside line measurement you just calculated. Use a pencil to draw a ring around the conduit at this point. Repeat this process for the left side, so that both outside lines are equidistant from the center line. If you calculated an outside line measurement of 7 ⁄2 in (19 cm), draw the first outside line 7 ⁄2 in (19 cm) to the left of the center line, and the second outside line 7 ⁄2 in (19 cm) to the right of the center line

Making the Bends

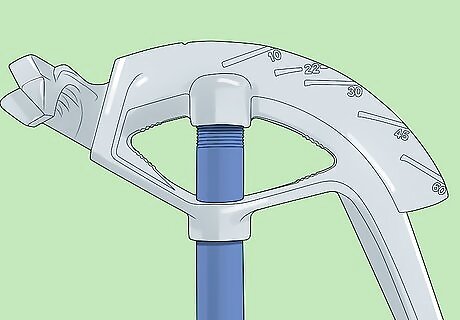

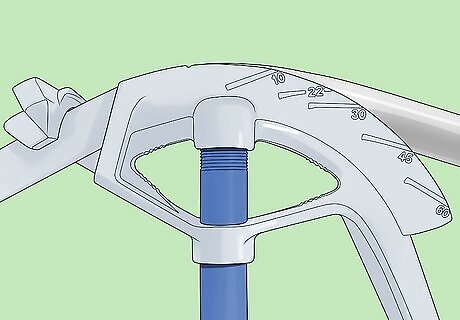

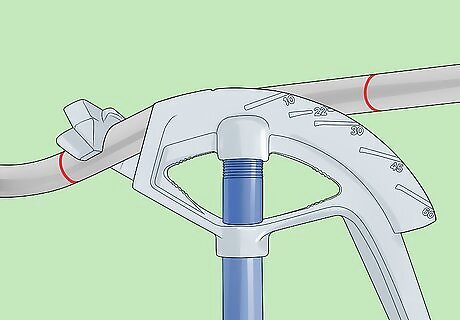

Align the center line on the conduit with the notch on the conduit bender. The conduit bender features an arched bender head which contains a channel for your conduit to slide into, as well as a series of marks, including a raised arrow mark and a single notch cut out of the side. This is attached to a sturdy pole. Stand the conduit bender tool upright with the bender head facing upwards and the bottom of the pole on the floor. Slide the conduit into the channel and position the center pencil line so it lines up with the notch on the bender head. The shorter side of the conduit should extend from the top and the longer side should point towards the floor. Steady the bottom end of the bender tool against the floor with your foot. For additional sturdiness, slide a bender boot onto the base of the tool and press down on this with your foot. The boot is a seesaw shaped cap for the base of the tool. It helps you angle the tool towards and away from your body for different bends while preventing side-to-side swaying movements. It’s covered with tread to help you steady the tool against the floor with your foot.

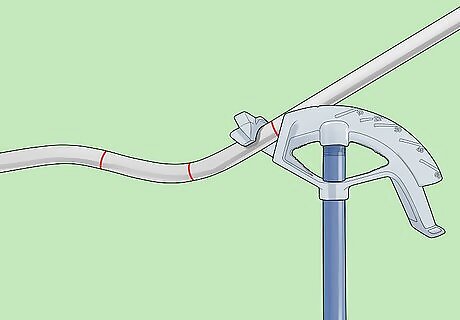

Push the end of the conduit down to create a 45-degree bend at the center line. Use your body weight to push the end of the conduit downwards over the bender head. Stop applying pressure when the bottom of the conduit lines up perfectly with the 45-degree mark on the bender head. When making a 3-point saddle, you should always create the center bend first. Squat into the bend and bend your knees as you push on the conduit. This will help you get a better look at the alignment on the bender head, and will prevent you from straining your neck or back. For a 30-60-30 saddle, push the conduit until it lines up with the 60-degree line on the bender head.

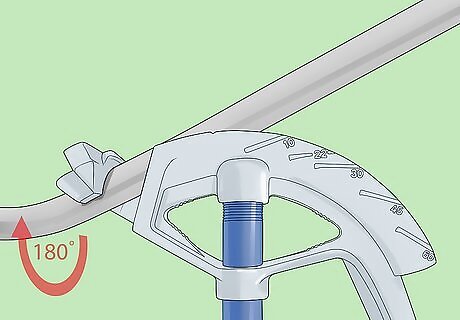

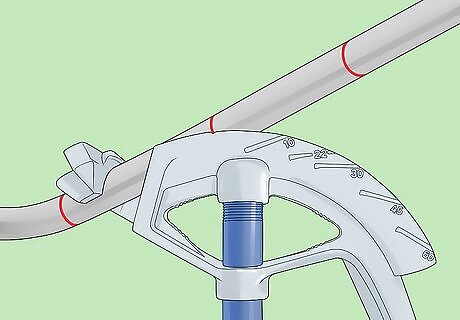

Slide the conduit down the bender head and rotate it 180 degrees. This will enable you to reach the first outside mark. Move the first bend past the bender head, sliding it away from your body, until the first outside mark sits on the bender head. Then twist the conduit around 180 degrees. The center bend should be in a “V” shape and the long end of the conduit will be up in the air, parallel to the floor instead of pointing down at it. Don’t pull the conduit out of the tool. You’re not creating any bends at this point; just repositioning the conduit.

Line the first outside mark up with the arrow on the bender head. While you used the notch as a reference for the center bend, you’ll use the raised arrow mark as the reference for the 2 outside bends. Align your pencil mark with the arrow for the first outside mark.

Use your body weight to bend the conduit at a 22.5-degree angle. Grip the short end of the conduit with your hands and push it downward, bending your knees and applying steady pressure as you create the bend. Stop when the bottom of the conduit lines up with the 22.5-degree mark along the bender head. You’ll make both outside bends at opposing 22.5 degrees. For a 30-60-30 saddle, keep bending the conduit until it reaches the 30-degree line on the bender head.

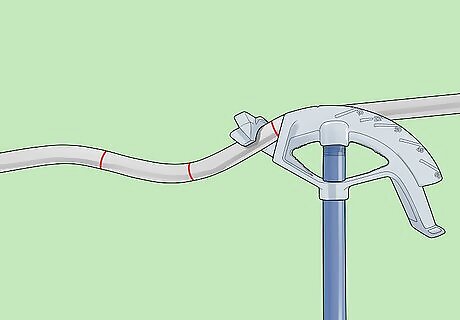

Lift the conduit out of the tool and line up the other outside line with the arrow. Once you’ve created the center bend and the first outside bend, slip the conduit out of the bender head. Rotate it so that the bender head faces towards the center line on the conduit, rather than away from it. Slide the conduit back into the bender head so that the other outside mark lines up with the raised arrow. Keep the bent pieces angled towards the floor, with the center bend positioned like a “V.”

Create the final bend at a 22.5-degree angle. The second outside bend should be a mirror image of the first outside bend. Once again, use your body to add steady pressure onto the end of the conduit to push it down until the bottom lines up with the 22.5-degree mark on the bender head. For a 30-60-30 saddle, make this final bend a 30-degree angle. With the 3-point saddle now complete, you’ll be able to secure the conduit in place right over the obstruction.

Comments

0 comment