views

- Feed a large sheet into the clamp bar of a bending brake, then lift the handles to bend the sheet to your desired angle.

- Lay your smaller aluminum piece on a block of wood cut to the desired bend radius. Tape a steel pipe to the top of the aluminum, then use an arbor press to bend it.

- Draw a line on the aluminum where you want to bend it, then clamp it to the edge of workbench with a wood block on top. Grab the aluminum and bend it upward.

Bending Sheet Aluminum with a Bending Brake

Purchase a metal bending brake online or at your local hardware store. A bending brake is a specialized metalworking tool used to create precise linear bends and folds in light gauge sheet metals, like the kind used to make flashing for doors, windows, and roofs. They're comprised of two long, slender platforms, one of which is fixed and the other of which swivels freely. Pulling up on a pair of small handles causes the moving platform to rotate upwards, bending the metal at varying angles to the fixed platform. Basic bending brakes typically retail for around $20-50, and are small enough to fit easily on most work benches or tabletops. A bending brake will be best suited for shaping flat, square sheets of light gauge aluminum. Heavy gauge aluminum bars or rods must be heat-bent using an acetylene torch and vice. This is a highly technical and potentially dangerous process best left to a professional metalworker.

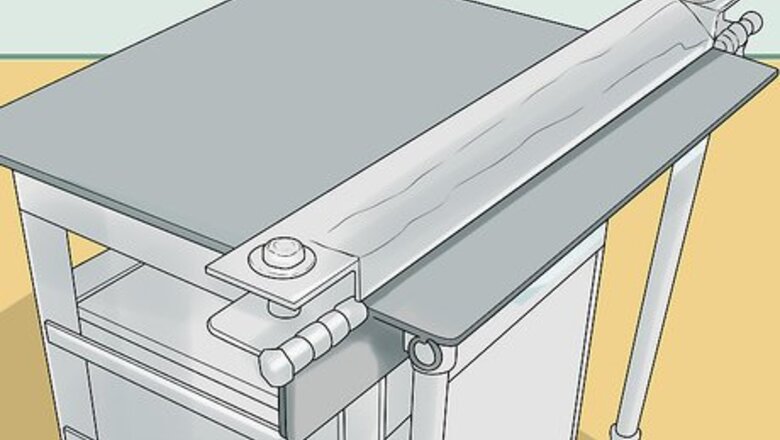

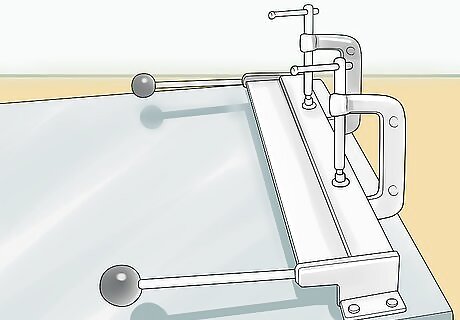

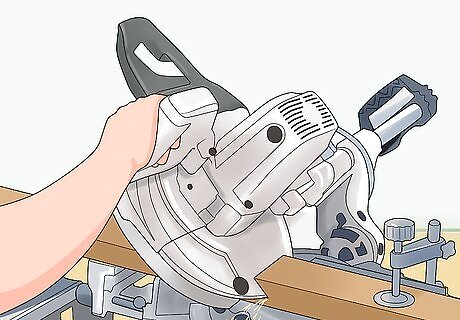

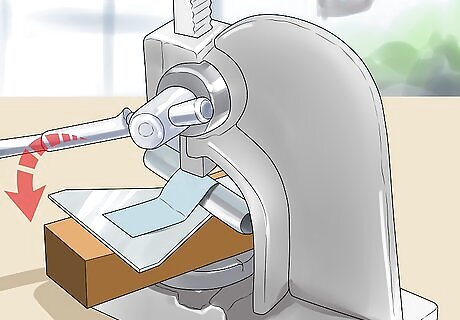

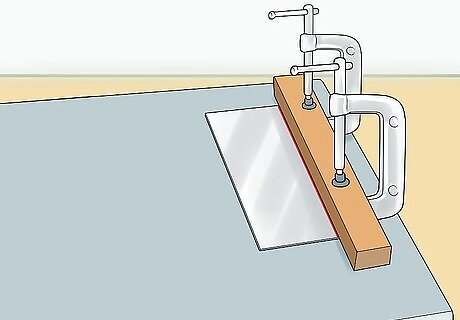

Insert your aluminum sheet into the brake beneath the removable clamp bar. Lift the clamp bar away from the rear of the brake frame and slide the sheet in perpendicularly to the direction you want to bend it. Then, place the clamp bar back down on top of the aluminum crosswise. Make sure the bar is seated firmly inside the frame. With the clamp bar in place, the two platforms that make up the frame of the brake should be positioned parallel to one another and overlap slightly.Tip: It may be necessary to alter the height of a non-removable clamp bar manually. You can usually do this by pulling a tab at one end of the brake and raising or lowering the bar as needed.

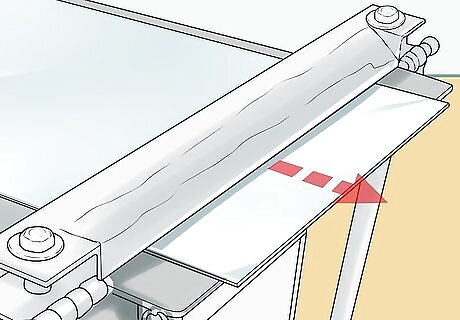

Adjust the edge of your sheet to set your desired bend line. Move the sheet around inside the brake as needed to align the bend point with the internal edge of the clamp bar (the side facing you). The section of the sheet beneath the clamp bar will fold up and around this edge to produce the bend. To guarantee a straight, precise bend, examine your sheet to make sure the outer edge is running parallel to the edge of the clamp bar.

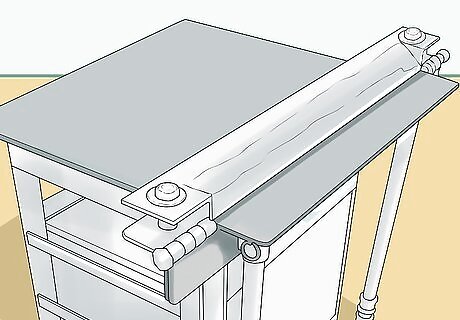

Attach a pair of C-clamps to hold the sheet in place. Position a clamp an equal distance from either end of the clamp bar, then screw them down tight. There’s no need to place the clamps directly over the aluminum itself. They’re just there to cinch the clamp bar tight to the swiveling apron of the brake. Some more expensive brake models have built-in clamps that can be applied by pulling down one or more handles. The apron is the part of the brake that swings upwards to actually create the bend when you lift the handles.

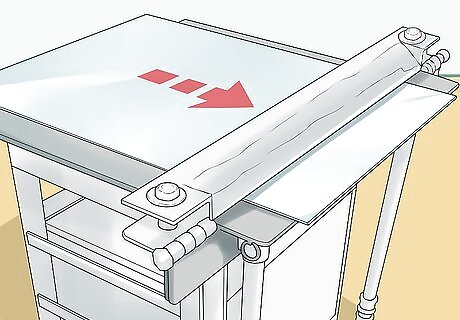

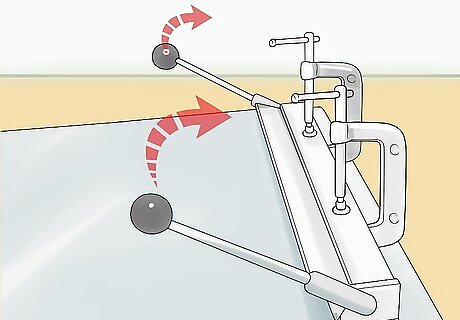

Lift the handles of the apron to bend your sheet to the desired angle. Go slowly—sheet aluminum is very soft, so you won’t need to use much force at all. As the apron comes up, it will gently fold the sheet around the edge of the clamp bar at your chosen bend point. Continue pulling up on the handles until your sheet takes on the shape you want. If your brake has a stop bar, set it to the exact bend radius you want to achieve. It will stop the movement of the apron automatically once the sheet reaches a predetermined angle. Don’t forget to undo the clamps and raise or lift off the clamp bar before removing your sheet from the brake.

Shaping Small Pieces with an Arbor Press

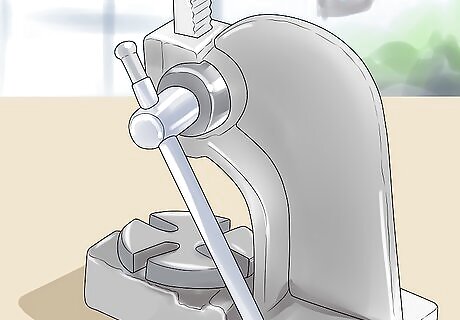

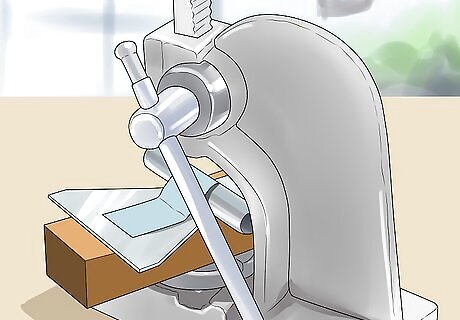

Buy or rent an arbor press online or at your area home improvement center. An arbor press is a type of compact hand-operated press used to install and shape small pieces of metal or similar materials. A standard arbor press is made up of three basic components: the table plate, or the flat surface that you place your work materials on; the anvil, which is the piston-like arm that exerts pressure on your materials; and the hand lever, which you crank to raise and lower the anvil. Look for an inexpensive arbor press online, or at any hardware shop or specialty tool store that carries metalworking equipment. In many cases, you can find a brand new arbor press for as little as $50-70. A standard arbor press is not much bigger than a coffee pot, which means it will fit comfortably in one corner of your work surface.

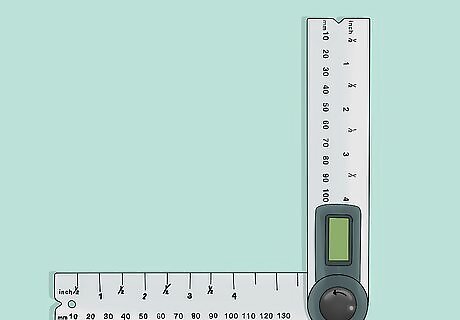

Use an angle finder tool to set the bend radius for your aluminum piece. Most angle finders feature two short legs that rotate independently of one another. On each leg, you’ll see a series of markings indicating various angles in relation to the opposing leg. Simply move the legs into the position that corresponds to the angle you need. You can pick up an angle finder tool from any hardware store or home improvement center for around $20. Digital angle finders tend to be a little pricier, but they’re considerably more accurate than analogue tools, which could be important if your project calls for precision. The exact bend radius you choose will depend on the nature of your project.

Cut your desired bend radius into the surface of a thick piece of wood. Once you’ve determined the necessary bend radius for your project, mark the angle onto the vertical edge of the wood. Then, use a table saw, miter saw, or circular saw to remove the excess wood inside the marking. The result will be a solid block with a V-shaped groove in the center, which you’ll use to shape your aluminum piece. Fashioning a V-block will allow you to quickly and easily press your aluminum piece to just the right bend radius using the pre-measured angle inside the notch. A scrap 2x4 or 4x4 board will do just fine for most projects.

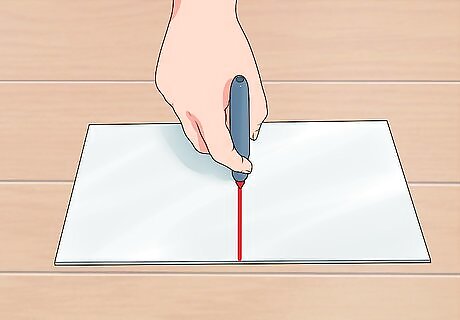

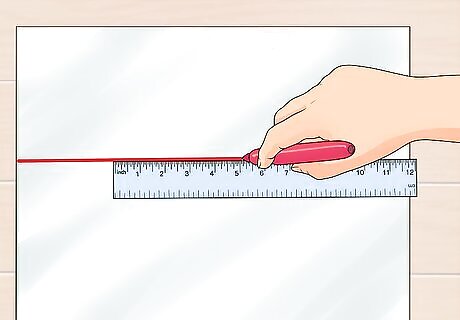

Draw a line along the surface of your piece where you want to bend it. Grab a ruler, align one edge with your chosen bend site, and run a felt-tipped marker or similar writing utensil down the edge. Make your bend line as bold and dark as possible to ensure that it’s plainly visible throughout the shaping process. You can also use a scrap board, the spine of a book, or another flat, square object if you don’t have a ruler handy.Tip: Extend your bend line over the outer edges of the aluminum and all the way across the opposite side. This will make it easier to sight-check with the section of the line on the upper face covered up.

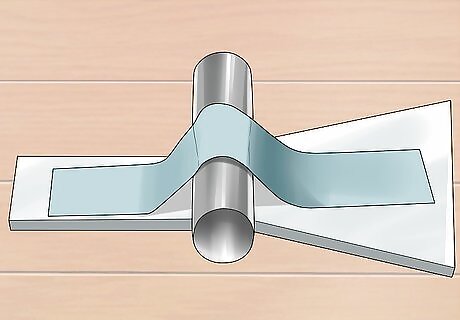

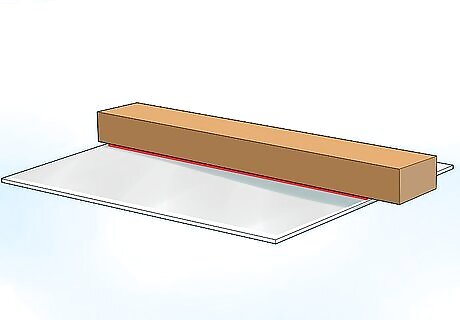

Tape a section of steel pipe to your piece directly over the bend line. Align the pipe with the bend line on the face of the aluminum that will end up on the inside of the bend. When you’ve got it where you want it, apply as many strips of tape as needed to make sure it’s secure. This pipe will serve as the “punch” around which you’ll bend your piece. As a general rule, the pipe you use for your punch should be roughly twice the diameter as your desired bend radius. To form a ⁄2 in (1.3 cm) bend, for example, you’d need to use a 1 in (2.5 cm) section of pipe. Construction sites, junkyards, and businesses that specialize in metalworking are all good places to scavenge for scrap steel. If you don’t have any luck there, you can also order the exact piece you need online. It's important to use a pipe or rod made from steel, as it's one of the only materials guaranteed to withstand the pressure exerted by the press.

Center your piece on the V-block and place it in the arbor press. Set up the block inside the press with the anvil centered over the top of the pipe. Double-check the position of the punch pipe in relation to the anvil of the press and the bottom point of the notch. When you’re satisfied that they’re all lined up squarely, you’ll be ready to begin bending your piece. If your aluminum piece isn't centered inside the press, you could end up with a crooked or misplaced bend, effectively wasting your materials.

Pull down on the lever to lower the anvil and bend the aluminum. As the lever goes down, the anvil will descend, pressing the punch pipe into the aluminum at the bend line. This, in turn, will cause the aluminum to conform to the angle of the notch in the V-block. When you’re done, simply remove the piece and wipe off the bend line. You may need to use both hands in order to generate enough force to bend the metal, depending on the thickness of your piece. Don’t forget that you can use your angle finder tool to confirm the precision of your work.

Tooling Aluminum by Hand

Draw a bend line across the section of your piece you want to bend. Run the tip of a dark felt-tipped marker along your planned bend point, using a ruler, straight edge, or long, straight object as a guide. Your bend line should stretch from one edge of your piece to the other, or at least be long enough to make it easy to set up your bend. If you make a mistake, wipe off the marker with a small amount of rubbing alcohol and start over. Your bend line needs to be nice and straight in order for the bend itself to turn out the same way.Tip: When drawing multiple bend lines, use your ruler to make sure that each line is spaced appropriately.

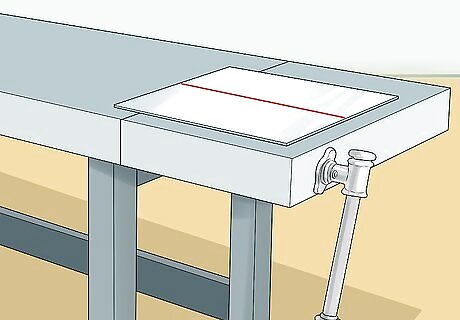

Set your aluminum piece on the edge of your workbench. Any decent-sized table or desk will also do, provided it’s sturdy and spacious enough to hold your piece comfortably. Position the piece so that the section you’ll be bending extends out over the edge. When selecting a suitable work surface, keep in mind that the friction of the metal could cause wear or more severe damage to wood and other soft materials.

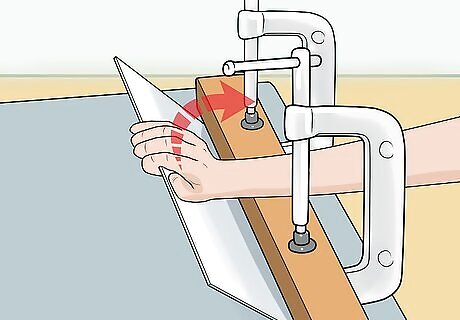

Place a length of scrap wood just behind your bend line. Square up the wood so that there’s a small amount of visible space between the bend line and the metal on the far side. The edge of the wood should be perfectly aligned with the bend line from end to end. An ordinary 2x4 will be perfect for most jobs, but you could also use a 2x6, 4x4, or another type of thick, heavy lumber. The most important thing is that it provide enough weight to anchor the sheet as you’re shaping it.

Clamp the wood to your aluminum piece using C-clamps. Slide the clamps over your stacked materials so that the shoe rests against the top of the wood and the anvil is braced against the underside of your work surface. Once the clamps are in place, twist the screw handles clockwise to tighten them down. Take a moment to lightly jostle the clamps and make sure they’re stable before proceeding. The shoe is the gripping surface located at the end of the screw, while the anvil is the gripping surface built into the arm of the clamp frame.

Bend the edge of your piece up around the wood by hand. Take hold of the section of metal overhanging your work surface and fold it up and around the edge of the wood manually. The amount of force this will require will depend on the shape and thickness your piece, but most ordinary sheets and plates should give quite easily. When you’re satisfied with the angle of the bend, loosen the clamps and remove the scrap wood to free your piece. If the piece you're working with has sharp, thin, or jagged edges, it's a good idea to wear a pair of rugged work gloves to protect yourself from accidental cuts. Tap the crease where the metal curves lightly with a rubber mallet to create a sharper bend. Manual bending works best for forming 90-degree angles, but you may also be able to produce other angles with steady pressure and a careful hand.

Comments

0 comment