views

Building the Platform

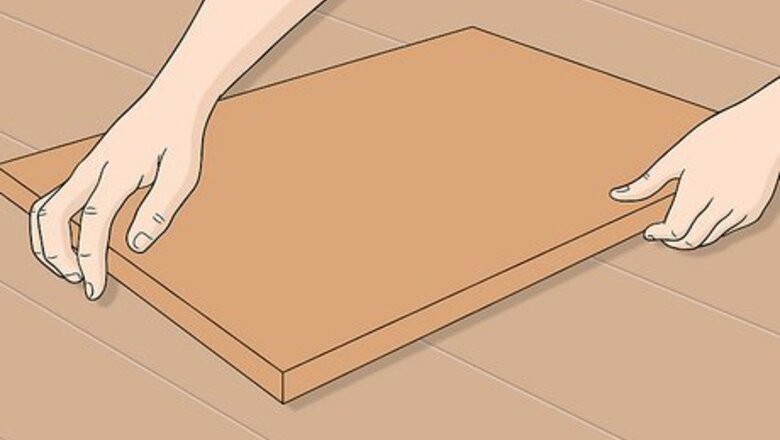

Build the basic platform for the wagon. The platform shown in the illustrations is about 18 inches (45.7cm) wide and 24 inches (60cm) long, but you can modify the size easily to fit your needs.

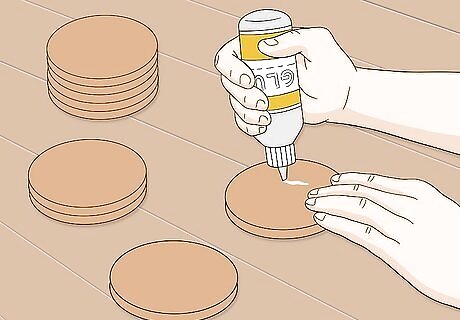

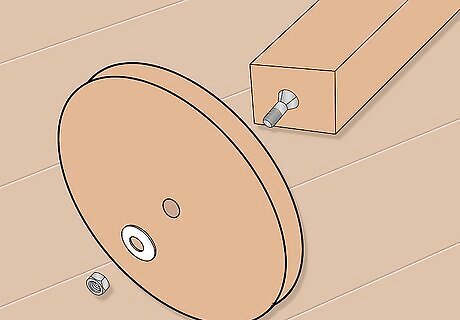

Build four wheels by gluing two 1X6 boards to each other (with perpendicular grain direction). Then scribe a circle on them, and cut them out with a jigsaw or bandsaw. Drill a 1/2 inch (1.2cm) hole in the center of each for the mounting bolts (described later).

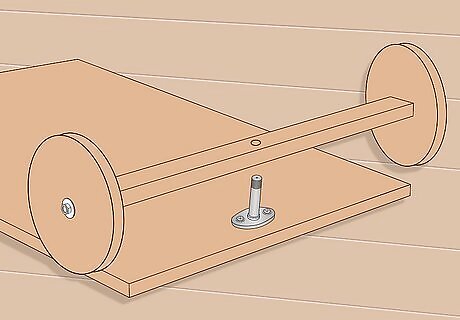

Making the Front Axle Swivel

Make the front axle swivel assembly by ripping two boards 2 X 2 inches (5cm x 5cm), the same length as the width of your wagon.

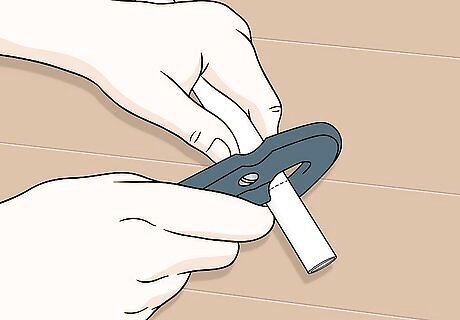

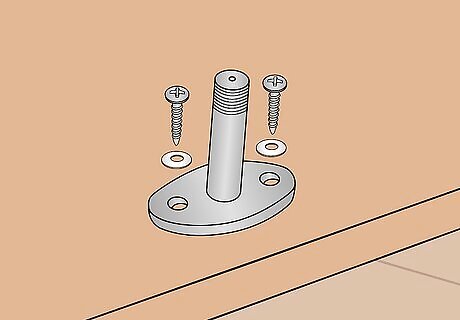

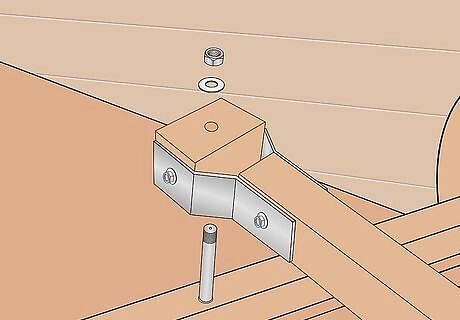

Drill a hole in the center of these two boards for the swivel pin. The illustrations show using a piece of metal pipe 3/4 inches (1.9cm) in diameter, so a 3/4 inch hole is drilled for this purpose.

Cut a section of pipe (or wood dowel, if preferred) 2 1/2 inches (6.3cm) long to fit in the swivel assembly holes. Use a flat washer as a bushing to allow the swivel to move freely when it is assembled.

Use a large screw or lag bolt to through-bolt the swivel and hold it in place. You may find you need a large fender washer to allow the screw to tighten if the hole is so deep the wood will not hold it.

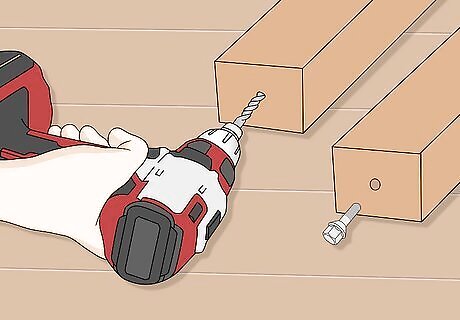

Drill the ends of the moving section of the front axle swivel assembly for the wheel bolts. A 1/2 inch (1.2cm) steel bolt works well for this assembly. Drill through the center of each wheel, slide the bolt through, slide a flat washer on the bolt, then stick the bolt into the hole in the end of the axle assembly.

Drill a hole though the axle assembly and the bolt that attaches the wheel to the assembly. Install a wood screw to lock it in place. You might grease the bolt so the wheel will turn freely and to reduce wear on this surface, or you may choose to install a metal bushing in the center of the wheel to reduce wear even further.

Attach the assembly to the bottom of the wagon base you started with.

Attaching the Handle

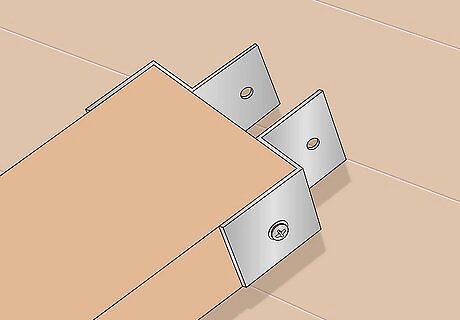

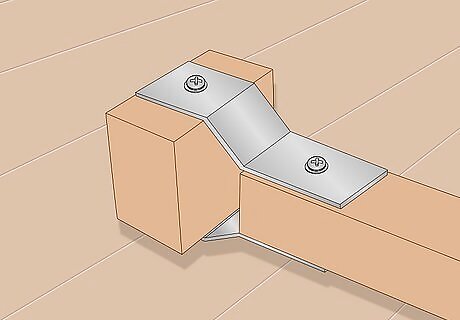

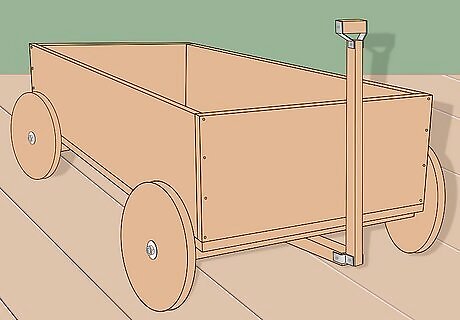

Bend two angle clips to attach the wagon handle with. Here, a 1 inch (2.5cm) by 1/8 inch (3.1mm) piece of aluminum flat stock is a good material to use, being easy to form and drill, and weather/corrosion resistant. Each side of the angle should be about 4 inches (10cm) long, and you will need to drill 3/16 inch (4.7mm) holes for the mounting screws on one side of each piece.

Mount these brackets at the center of the swivel/axle assembly, allowing space for the pull handle to fit between them freely. You might rip this piece of stock (1 1/2 inches (3.8cm) square by 3 feet (91cm) long) before mounting the attaching brackets to make sure they are positioned correctly.

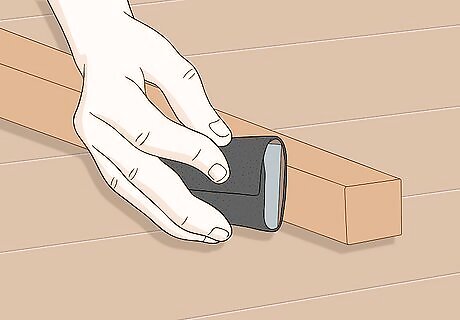

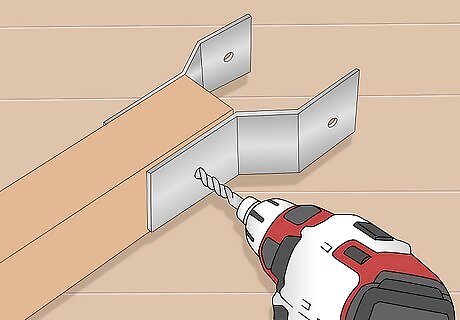

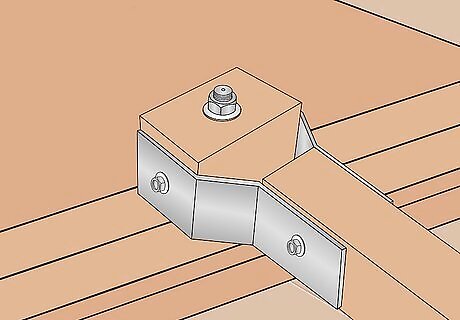

Rip the stock, (described in the step, above), sand the edges smooth, and position it between the brackets so the attaching bolt can be inserted. A 1/4 inch (6.3mm) bolt 2 1/2 inches (6.3cm) long will hold this piece in place. You can dimple the end of the bolt where the threads come out of the nut to prevent it from loosening during use.

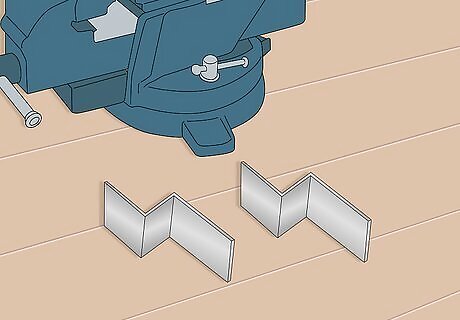

Build the yoke that will hold the grip at the other end of the handle. Again, the aluminum flat stock is an easy material to use for this step. Form two matching pieces in a squared zee shape (see illustration), drill it for the mounting screws, and smooth the edges with a file or sandpaper so there isn't a risk of scratches when handling it.

Fit a block of wood 1 inch (2.5cm) square between the ends of the yoke. Then center drill it for a 1/4 inch (6.3mm) bolt (or all thread rod) to attach it. Be sure to drill as nearly in the center as possible, using a bit long enough to drill completely through.

Thread the bolt or all-thread rod through the yoke, the handle block, and out the other side of the yoke. Then thread a nut on the end (or both, if you are using all-thread rod).

Tighten the assembly. Cut off and grind smooth any protruding bolt threads.

Assembling the Rear Axle

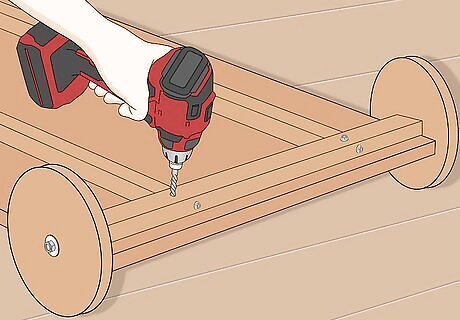

Build the solid rear axle. Cut a 1 1/2 by 1 1/2 board the same length as the width of your wagon, and cut two spacer blocks to support it and allow clearance for the wheels to turn.

Drill and screw the spacer blocks and rear axle into place. Then drill the ends to allow the wheel mounting bolts to be inserted. Drill and pin these bolts into place the same way you did on the swivel assembly.

Adding Sideboards and Finishing

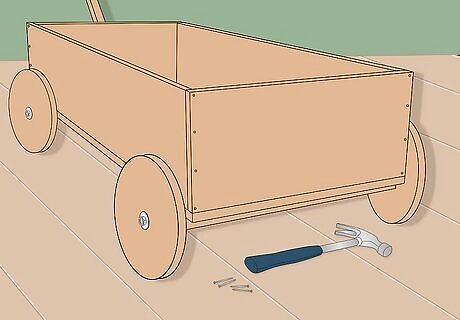

Cut and fasten the sideboards on the wagon platform. Use wood screws or brad nails to attach these sides.

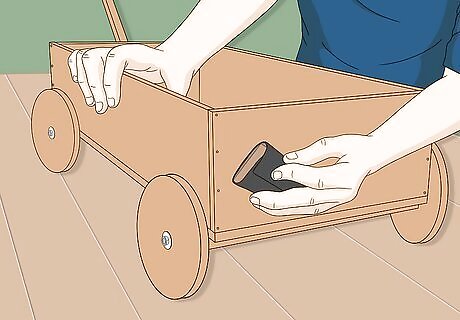

Sand any rough or splintery edges with a power sander or sandpaper. Be especially careful if this wagon will be used by a child.

Finished.

Comments

0 comment