views

Quick P-Trap Fixes

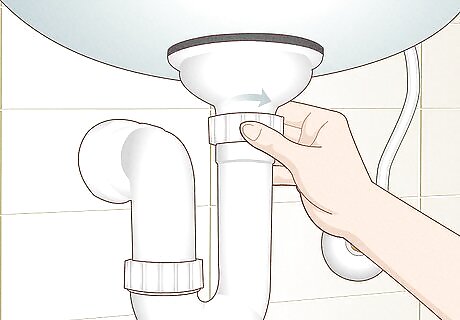

Inspect the P-trap for signs of obvious problems. If the P-trap’s piping and connections appear to be lined up fairly well and in good shape, there’s a good chance you can fix the leak in less than 2 minutes by properly tightening the slip-joint nuts—the collar-like connectors that join together sections of pipe. You may have to disassemble and replace some or all of the P-trap, however, if you spot any of the following: Cracks or other signs of damage in the piping or connectors. Corrosion on the pipes or connectors, if they’re metal instead of PVC. Piping that is noticeably (not just slightly) misaligned either vertically or horizontally at the connection points. Not sure what you’re looking at under the sink? The P-trap begins where it connects to the tailpipe that comes out of the bottom of the sink basin, then makes a U-shaped curve. From there, it either connects to a mostly-horizontal drainpipe that disappears into the wall or makes another curve to connect to a vertical drainpipe that goes into the floor.

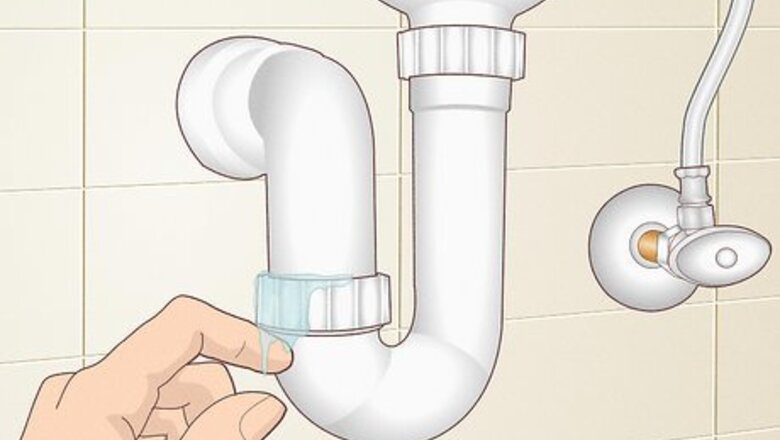

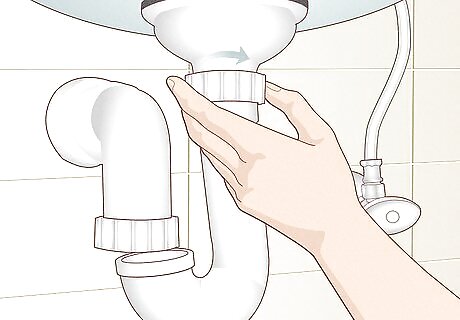

Loosen each slip-joint nut about 1-2 full turns. PVC slip-joint nuts can often be loosened by hand alone. One-by-one, grip each of the slip-joint nuts in the P-trap and twist them counterclockwise about 1-2 rotations. If any of the nuts won't budge by hand (or if they're metal nuts), grab a set of slip-joint pliers (e.g, Channellocks). Grip the nut with the pliers while steadying the adjacent pipe with your free hand, then turn counterclockwise about 1/2 of a turn. Loosen it about 1-2 full turns by hand. All P-traps have at least 2 slip-joint nuts: one where the P-trap meets the sink drain’s tailpipe, and one where it meets the main drainpipe. Your P-trap may also have slip-joint nuts at one or both ends of the U-shaped curve.

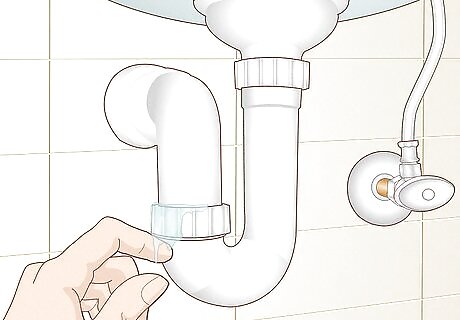

Nudge any pipes that look crooked into better alignment. If the vertical sections of pipe line up nicely, and the same is true for the horizontal sections of the P-trap, skip this step. Otherwise, now is the time to fix any misalignment that can affect the slip-joint nut's seal and cause a leak. With the nuts now loosened, use your hands to ease the sections of pipe into better vertical or horizontal alignment. If the misalignment is more significant and you can’t nudge the sections into place, you’ll have to remove the P-trap for repairs and reinstallation. PVC P-traps easily get nudged out of alignment and are usually just as easy to nudge back into alignment. Metal traps aren’t so flexible but can still be slightly adjusted into better alignment.

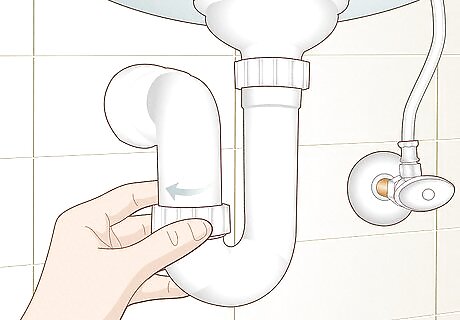

Re-tighten—but don’t over-tighten—all the slip-joint nuts. For each nut, turn it clockwise by hand until you feel solid resistance. Then, grab a pair of slip-joint pliers and adjust the jaws so they grip around the nut firmly. Turn clockwise until you feel moderate resistance. For a PVC nut, this may take about 1 1/2 turns; a metal nut may or may not require more rotations. The slip-joint nut (or the package it originally came in) may have a marking on it like "TPFT 1.5." This indicates that you should tighten it with pliers 1 1/2 rotations past hand-tight. If the nut doesn't have a marking like this, you'll just have to use your best judgment. As a general rule of thumb, you don't want to over-tighten during plumbing repairs.

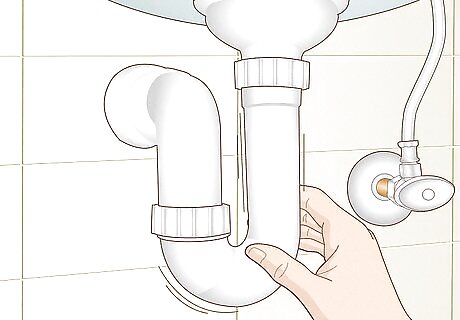

Use a dry item like toilet paper to test for leaks. Now that you’ve properly tightened the slip-joint nuts, turn on the faucet taps full-blast. Wrap a strip of toilet paper around your fingertip, then rub your fingertip around both sides of every slip joint nut you just adjusted. If the paper on your finger remains dry, the leak is fixed. Otherwise, there's still one more quick fix you can try before starting a more involved (but still DIY-friendly) repair job. Alternatively, dip your fingertip in baby powder or cornstarch, or use a facial tissue instead of toilet paper.

Apply pipe sealant to the threads as one last quick-fix option. If you still find a leak at one or more of the slip-joint nuts, loosen them once again, this time until you can see the threads on the pipe. Grab a tube of pipe sealant, squeeze a glob of the toothpaste-like material on your finger, and apply a thick layer of it all around the threads on both the pipe and on the underside of the nut. Tighten the nut as before, wipe away the excess sealant, and test for leaks once again. If this fix still doesn't do the job, it's time to remove and repair the P-trap. Use pipe sealant, not caulk or another adhesive or waterproofer. Unlike other options, pipe sealant won’t prevent you from easily undoing the slip-joint nut in the future. Rex Cauldwell Rex Cauldwell, Licensed Master Plumber When fixing a leaky p-trap under a sink, start by loosening the slip nuts on either side of the trap and removing it for inspection. Clean out any debris, replace worn gaskets, and reinstall the p-trap, tightening the slip nuts securely but not excessively. Perform a bucket test by sealing the drain and filling the sink with water to check your work before putting the sink back into regular use.

Repairing or Replacing the P-Trap

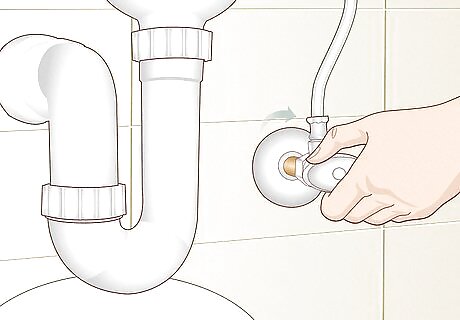

Shut off the water supply and put a bucket or towels under the P-trap. Remember that there’s always some water in the P-trap, so have either the bucket or towels ready to go before you disconnect it. It’s also a good idea to shut off the water supply so that someone (even you) doesn’t accidentally turn on the tap and send water gushing down the sink drain and into the sink cabinet! The hot and cold shutoff valves should be located under the sink. Turn them both clockwise to shut off the water supply.

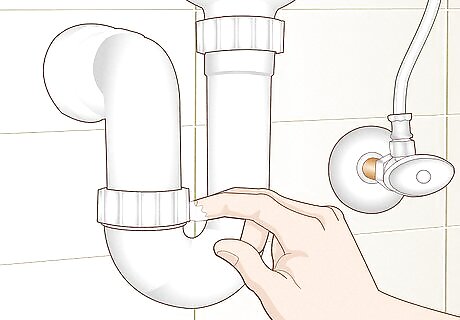

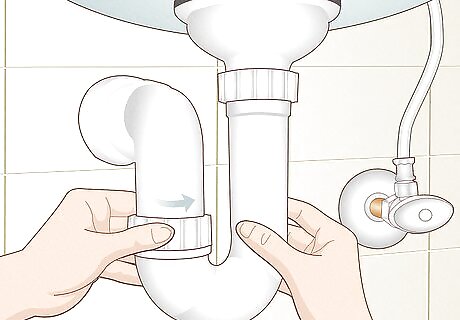

Undo the slip-joint nuts at both ends of the trap to remove it. Twist counterclockwise to disconnect the nut that attaches the P-trap to the sink’s tailpipe, then do the same to disconnect the nut that joins the P-trap to the drain line. Pull away the entire P-trap and pour out its contents into the bucket or pile of towels. You may be able to undo PVC nuts by hand, but you’ll most likely need slip-joint pliers to loosen metal nuts. Plug up the exposed opening to the drain line with an old rag to prevent sewer gasses from escaping.

Inspect the P-trap, including all nuts and O-rings, for signs of damage. If you’ve already pinpointed the location of the leak, check there first—you’ll usually find that either the slip-joint nut is damaged or the rubber O-ring that fits inside is crumbling apart. Continue to check all other parts of the P-trap assembly for signs of wear, damage, or (if metal) corrosion that you may not have noticed. It makes sense to replace everything that isn’t in tip-top shape. This is also a good time to clean out the P-trap with a bottle brush or a bent wire coat hanger. The rubber O-rings compress and create a watertight seal as you tighten the slip-joint nut.

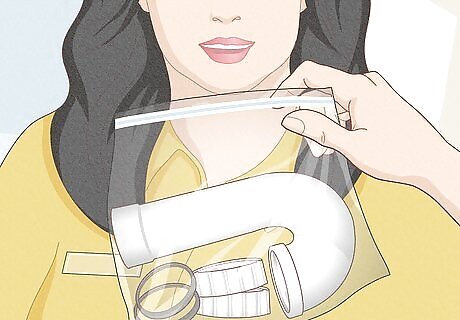

Take the whole P-trap assembly to a store to get replacement parts. There’s simply no better way to make sure that you get the exact matching parts you need. No matter what condition they’re in, buy all new rubber O-rings for each slip-joint nut. Also replace any nuts that are damaged or deformed in any way. If the removed trap had multiple leaks, widespread damage, or was noticeably out of alignment, it’s best to just buy a whole new P-trap setup (pipe sections, nuts, and O-rings) to assemble and install. Any hardware, home improvement, or plumbing supply store should have all the parts you need. You can buy a complete P-trap kit if you have a typical setup, or purchase parts individually.

Reassemble the P-trap with any replacement parts you bought. If you’re threading a new slip-joint nut onto the P-trap, make sure to line up the threads so that the nut isn’t attached to the pipe at an angle. Also be sure to put a rubber O-ring inside each slip-joint nut before connecting any two sections of the P-trap pipe. While it’s not a necessary measure, adding some pipe sealant to the threads as you reassemble the P-trap may provide some added leak protection.

Secure the P-trap back into place and test it out. Make sure the top of the P-trap and the bottom of the sink’s tailpipe are properly aligned, then tighten the slip-joint nut by hand and then with slip-joint pliers until you feel moderate resistance. Repeat the process where the end of the P-trap meets the drainpipe that disappears into the wall or floor. Now that the P-trap is reinstalled, open the hot and cold water shutoff valves (by turning clockwise), turn on the faucet, and check for leaks with baby powder or tissues again. If you’re still dealing with a leaky P-trap, disassemble it and give it another try. Or, just accept that you’ve done your best and call a plumber.

Comments

0 comment