views

X

Research source

Lucky for you there's a way you can try to repair your guitar neck on your own.

Checking the Straightness of the Guitar Neck

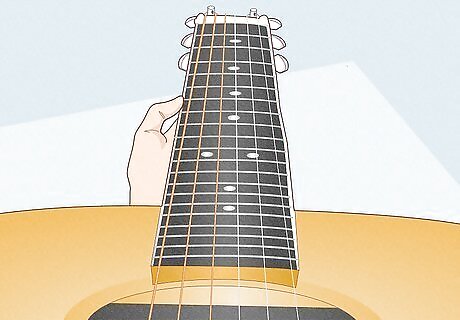

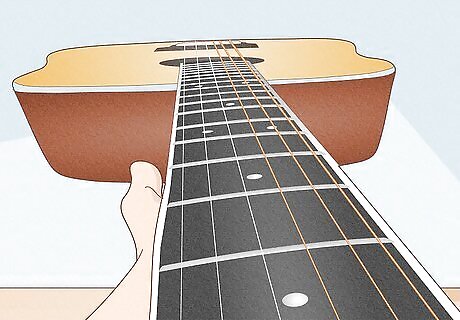

Eyeball the neck to check for warping. Take your fully strung guitar in your hands and hold it strings up, level with your eyes, and pointed toward a generalized light source. Look from the bridge, where your strings begin under the sound hole, up the neck to the tuning keys. A good light source for this visual check would be a well-lit window. If your guitar isn't actually warped, you should only notice small dips in the shadow cast by your guitar strings on the fretboard at the fourth, fifth, and sixth bottom frets. Other variances in the shadows cast by your strings on the neck are an indication of warping. In some cases the neck might not be warped, but the frets of your guitar may have become somehow misaligned. If this is your case, you should notice one or more frets higher or lower than other surrounding frets. Sometimes frets become misaligned because of warping in the neck of your guitar. When you notice misaligned frets, inspect the area carefully. The upper frets of your guitar should be almost perfectly straight, if not perfectly straight. Deviations in the top frets are a good indication that you have a warping problem. Don't look to the wood of the neck and fretboard or its edge to determine warp. This part of your guitar can become worn down over time from playing, and can make the neck appeared warped even when it is not.

Repeat your eye-check from the headstock to the body. Rotate your guitar so that the base is facing away from you and your view begins with the headstock, where the tuning pegs are. Hold your guitar level with your eyes but pointed at a generalized light source. Just as you did previously, use the shadows cast by the strings to evaluate the straightness of the neck. There should only be small dips in the shadows only on the fourth, fifth, and sixth bottom frets. Sometimes warping is harder to notice from one end of your guitar than the other. By performing a visual check of the neck of your instrument from both the body and the headstock, you'll stand the best chance of noticing warping. You may want to mark any unnatural variances in the neck you see with a piece of tape. Especially for necks that have severely irregular warping, jotting down or marking where you notice the distortions in the wood will help you make more precise adjustments later.

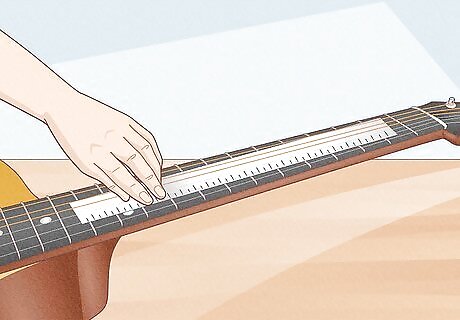

Use a straightedge to check the neck precisely. If your visual check of your guitar didn't reveal any irregularities, this does not mean that your guitar neck isn't warped, only that there is no obvious warp in your instrument. And even if you noticed warping, a straightedge check can confirm your observations or help you determine the extent of the warp. Place your guitar on a level, stable surface, like a clean workbench or table. You are going to use the strings of your guitar as your straightedge. To do this you should: Press the sixth string of your guitar at the first and twelfth (or first and fourteenth for electric/steel guitars). There should only be a tiny gap, about 1/64 of an inch (.4 mm), between your string and fretboard on the sixth fret. No gap is an indication of unnatural back-tilt, which can be fixed by adjusting the truss rod. Press the sixth string at the eighth and highest frets. The string should lie flat along the board along the midpoint (approximately the twelfth to fourteenth frets). A gap here indicates a rising warp in the neck of your guitar. Press your sixth string along the first and last frets. If there is a small gap between the string sixth fret the warp in the neck is centralized in the upper part of the neck away from the body. This can usually be fixed by adjusting the truss rod. If your string and sixth fret form a gap larger than 1/64 of an inch (.4 mm), the neck is warped. Hold the sixth string at the first fret and slowly slide down the fretboard with your other hand. As you slide down the frets, if the gap at your sixth fret decreases, the neck is warped and will need to be straightened.

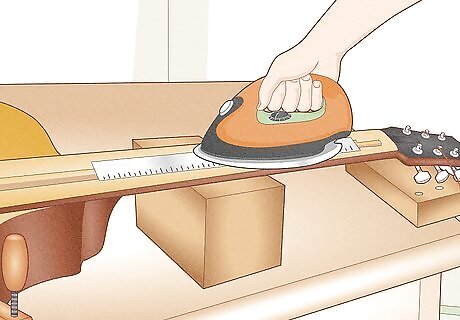

Repeat the straightedge test and use a ruler to check the frets. Now that you've performed a straightedge test with the sixth string, you'll have to repeat the test with the first string. This will ensure both sides of the fretboard are level. If your inspection has not found irregular warping, it may be your frets causing buzzing or other distortions. To check your frets, take a straight metal ruler and lie it along the fretboard. A misaligned fret may only be out of alignment by a few thousandths of an inch. This might not be observable with your eyes, but if you lay the metal along the frets, the misaligned fret will cause the ruler to seesaw slightly back and forth.

Removing the Frets from the Neck

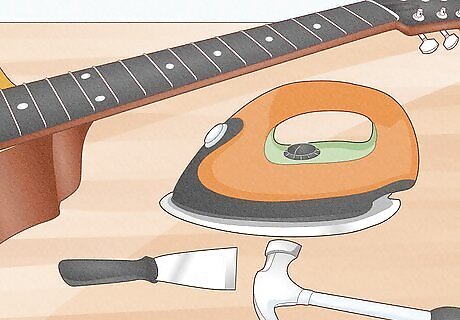

Prepare your tools and guitar. You'll want a flat and clear surface to work on while removing frets from the neck of your guitar. You're going to use the steam from your iron to loosen the glue connecting the frets to the neck, and then with your hammer and scraper, you'll be chiseling off the frets. To do this, you'll need to remove the strings from your guitar. You may want to hold the neck of your guitar into place with a rubber ended clamp or some other suitable clamp for woodwork. This is not necessary, but can make removing the frets easier. Make sure your iron has plenty of water. You'll need lots of steam to loosen the glue fastening your frets and guitar neck. You may want to bring some extra water in a pitcher in case you run dry mid-steaming. It is possible that damage could occur to your guitar during this process. If you have an expensive guitar, you may be better off having a professional repair the neck of your instrument.

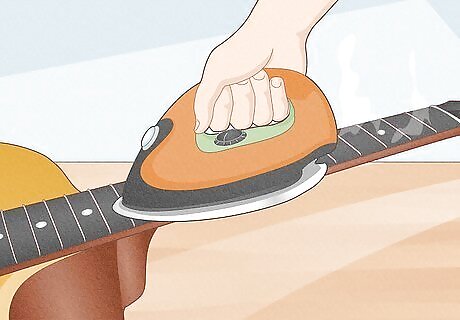

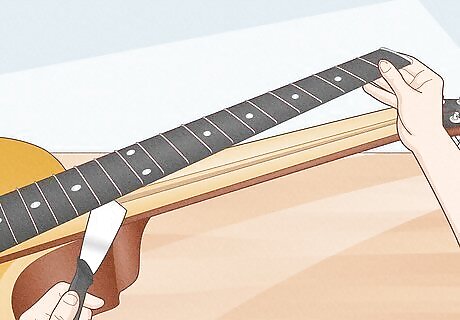

Apply steam to the top of the fretboard. Warm up your iron and set it to its hottest setting. Now you are ready to place the iron on the topmost segment of the fretboard to begin steam-loosening the frets. It should take about five minutes before the frets begin to loosen. At the five minute mark, or shortly before, take your scraper and begin firmly pushing it between the fretboard and the neck from the side of the neck of the guitar. Depending on your guitar, you may need to apply more or less steam to the neck to loosen the glue. Test the bond between fret and neck every minute or so be probing it with your scraper. The fretboard and neck will become very hot from the heat of your iron. Be careful when touching the neck or handling your guitar. To prevent being burned or scalded, you may want to wear a pair of gloves or wrap the neck of your guitar in a towel after removing your iron. When the glue has sufficiently loosened, you should be able to get an inch or two of your scraper (or putty knife) inserted between your fret and neck. This should be enough to hold your scraper in place between the two parts unassisted.

Chisel free the frets from the neck of your guitar. Take your hammer and gently but firmly tap your scraper on its handle until it pushes through to the other side of the neck of your guitar. When you find stubborn resistance to your hammer tapping/chiseling, you should pause and apply more steam to the frets of your guitar. Keep your scraper at a right angle (forming an L-shape with) the neck of your guitar. This way you'll be able to tap the protruding end and the handle to wedge the fretboard free evenly. This will help prevent damage to the neck due to unequal stress being applied by your scraper. Removing frets from the neck of your guitar can be a long an involved process. You should work slowly to prevent the wood from cracking and splintering. Damage to the neck can permanently ruin it.

Continue until the fretboard is removed from the neck. Work your way down the fretboard, alternately applying your iron to steam-loosen the glue and your hammer/scraper combination to separate the board from the neck. As you move down the fretboard, you should notice the fretboard come free more easily. Even when the fretboard begins coming free more easily, work slowly and methodically. Working too fast can cause damage to the neck or fretboard of your guitar. Once the glue has become loosened, try to wiggle your scraper back and forth in the direction of the still-glued segments. You may find this loosens the glue more easily.

Repairing a Warp in the Neck

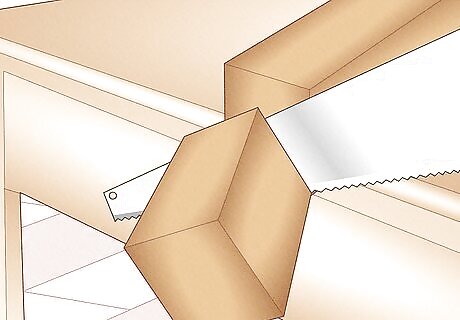

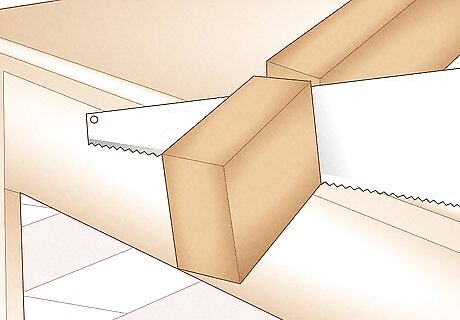

Cut cradle block for your guitar neck with your saw. You'll want your cradle to be made of a hard wood, like oak. This will prevent damage to the neck while providing resistance you need to correct the warp. Use your tape measure to find the distance between the area of the neck that is warped and the surface you are working on when the body of your guitar is laying flat. This will be the height of your cradle block. The length of the block should be about five inches (12.7 cm), and its width an inch (2.54 cm) wider than the neck of your guitar on both sides.

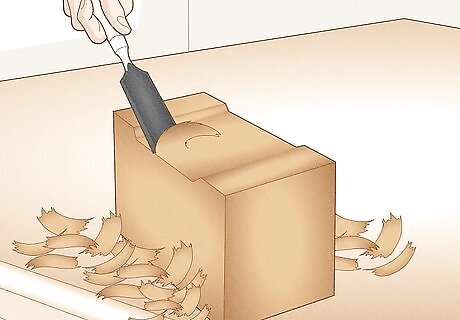

Hollow a trough to hold the neck of your guitar in place. Now you are going to notch the cradle block along the top to make a level trough in which your guitar will nest. This will prevent your guitar from irregular forces that could cause the neck to crack, or from the instrument slipping while you are straightening the warp. Your trough doesn't need to be too deep; a ¼ inch (6.35 mm) deep should be sufficient to hold your guitar in place. This will also help prevent stress fractures in the wood of the neck.

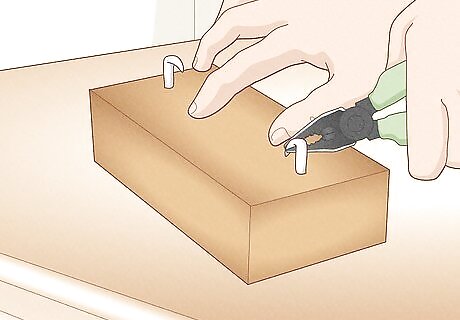

Cut your tension block. Take your 2 by 4 and cut it down to a manageable size - 6 inches long (15.24 cm) should be sufficient. Then lay it on its wide side and make a mark in the middle of the board three inches from either side. To either side of this midpoint mark, measure 2 inches (5 cm) and make a mark in the center of the board. The midpoint mark is where the headstock of your guitar will overhang. The marks to either side of the midpoint will be where you add tension rods, which you will use to straighten the warp of your guitar.

Add and shape the tension rods. These will be made from nails. With your hammer, pound a nail into the two spots you marked on both sides of your midpoint. The nail will need to protrude through to the other side of your 2 by 4. To shape your tension rods, you should bend the nails with pliers so the protruding nail ends point to the corresponding outside ends of your board. Be careful you don't damage what is below your 2 by 4 when you pound the nails through the board. You'll want your nail to extend 2 to 3 inches (5 to 7.6 cm) out the opposite side of your 2 by 4.

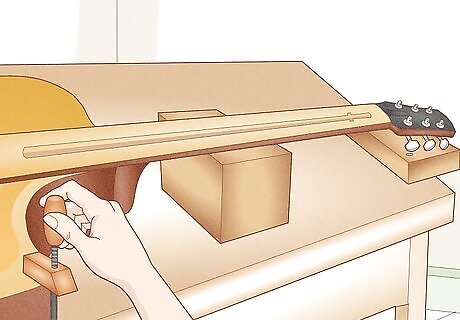

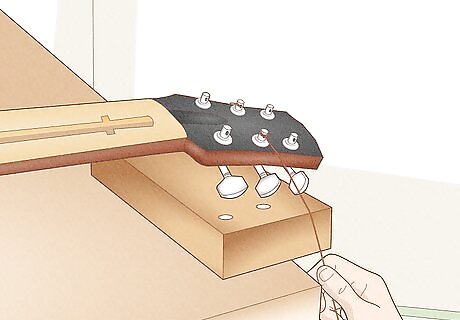

Secure all necessary parts to your work space. At one end of your work space, you should clamp your tension block firmly into place. Position your guitar so that the headstock directly overhangs the midpoint mark you've made on your tension block. When you have aligned your tension block, lift the neck and place the cradle beneath it, nesting the neck into the cradle where the warp is centralized. Then you should clamp the body of your guitar firmly to your work area at its base. You may want to put small pieces of rubber between your clamp and guitar, guitar and work area, and clamp and work area. These small pieces of rubber will prevent damage to your guitar or work area. At this point, your guitar should be clamped at the base to your work area, the warped part of the neck should be nested in your cradle, and your tension block should be clamped to the work area with the headstock of your guitar overhanging its midpoint.

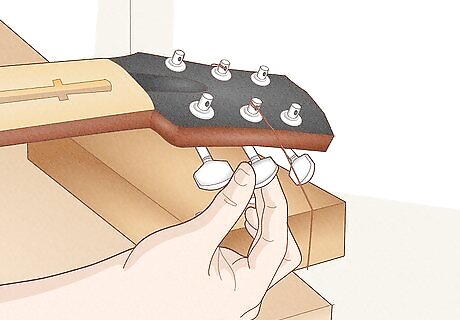

Attach the B and A tuning pegs to your tension rods. Now that your guitar is firmly held in position and supported, you need to insert the thickest guitar string you have into the A and B tuning pegs, which are the middle tuning pegs on either side of the headstock. Wrap the string around the top of the peg several times to affix it in place, then take each loose end around each pegs' closest edge and down toward the tension rods. Place your last two rubber guards in between the string and the headstock so the string does not damage the wood, and then wind the strings tightly around the tension rods. Your low E string should work nicely for warp repair purposes. Thicker guitar strings will allow you to apply more tension to the neck to correct the warp.

Adjust the tuning pegs to repair the warp in your guitar. By tightening or loosening your A and B tuning pegs, you'll be applying tension to the neck of your guitar. This tension is how you will correct the warped neck. But before you start applying tension with your tuning pegs, place your straightedges to form right angles ( L-shapes) with the base and the top of the neck. Using the straightedges, you'll be more able to see if the warp has been corrected. If the top of each straightedge is aligned and level, your warp has been corrected. You can also lay your straightedge longways down the neck of your guitar. This may make it easier for you to see lengthwise warping. You may have to make several small adjustments before your warp is corrected. Be careful not to apply too much tension to the neck of your guitar; this could result in the neck cracking. Once the neck is straight, you should add a half turn to each tuning peg to give the slightest backward bowing in the neck of your guitar.

Apply heat to set the new neck shape. Lay a metal straight edge, like a steel ruler, along the now straightened neck of your guitar. This will act as a buffer between the wood and the direct heat of the iron while helping to evenly distribute the heat. A medium-low setting will help prevent you from applying too much heat too fast, which could do damage to the wood. A constant temperature of about 350 to 400 degrees Fahrenheit (176 to 204 degrees Celsius) applied to your guitar neck for about two to three hours should help the neck hold its repaired shape. Afterward, you should allow the wood to cool for about a day.

Reattach your fretboard and restring your guitar. The neck of your guitar should now be repaired. All you need to do is re-glue your frets to the neck, restring your guitar, and it should play as good as new!

Comments

0 comment