views

Cutting and Taping the Nozzle

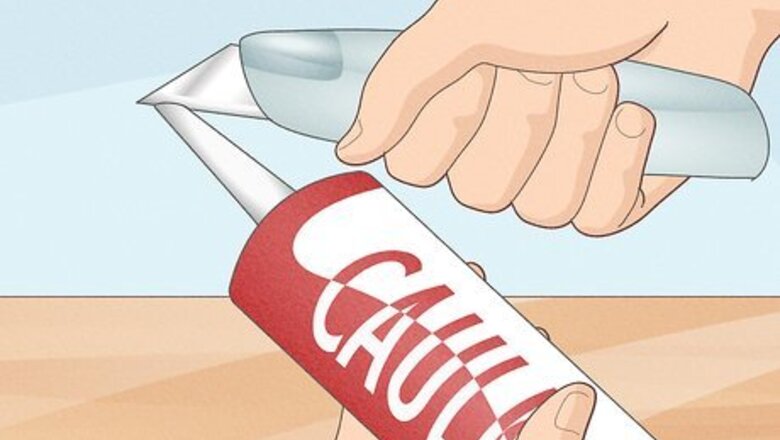

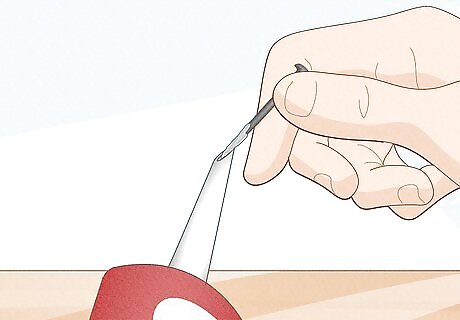

Cut a vertical seam on one side of the nozzle with a utility knife. Clean the nozzle off with a rag to remove any drips. Then, take the tube out of the gun and lay it sideways on a stable surface. Brace it against the table with your non-dominant hand. Grab a utility knife and puncture the base of the nozzle with the tip of your blade. Drag the blade up to cut a straight line through one side of the nozzle, all the way through the tip. You’re going to re-tape the nozzle when you use it in the future. This cut won’t cause any future leaks or damage the silicone or anything like that. Do not cut all the way through to the other side. What you’re doing here is making it easier to remove silicone from the nozzle once it dries out. If you cut all the way through, this won’t work. This is likely the most efficient method, but it does require a bit more time than the other options. It’s also likely unnecessary if you plan on reusing your silicone tube within the next couple of days.

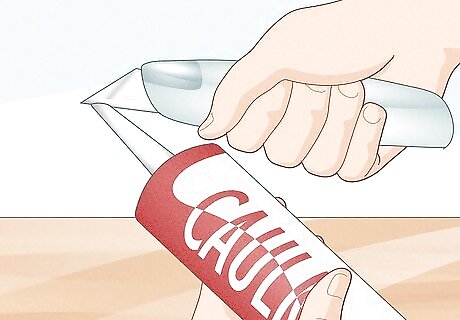

Wrap the nozzle tight with electrical or masking tape. Once you’ve finished your cut, grab a roll of electrical tape. Masking tape will work as well. Starting at the base, wrap the tape around the nozzle tightly. Continue working your way up to wrap the nozzle in a series of concentric layers of tape. Leave the very tip of the nozzle open. When you cut the nozzle, you released the pressure inside. Air may have crept inside, so don’t tape the tip off just yet.

Squeeze a bit of silicone out to fill the nozzle entirely. Put the tube back into the caulk gun. Tighten the hook against the back of the tube and point the tip on a scrap piece of wood or a paper plate. Pull the trigger on your gun once or twice and let the silicone spill out. This will fill in the nozzle with silicone entirely and keep any air pockets from getting trapped inside.

Tape the tip off and store your silicone. Once you’ve filled the nozzle out, grab another piece of tape and wrap it over the tip of the nozzle. This will keep some of the air out, but the good news is that you don’t really care if a little air gets inside. Removing any silicone that dries out in the nozzle will be easy as pie. You can just fold a piece of tape vertically over the tip. Alternatively, you can wrap the tip by pulling the tape around the opening in a circle and squeezing the adhesive sides together at the top. Either option will work just fine.

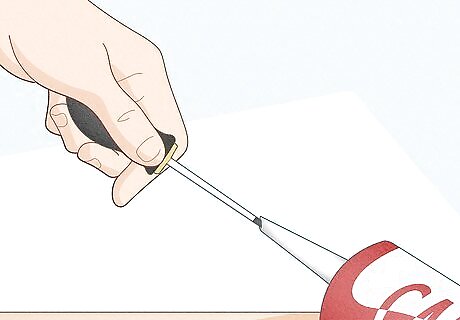

Push the dry silicone out with a screwdriver to reuse it. Once you’re ready to reuse the caulk, peel off all of the tape and grab a flathead screwdriver. Near the base of the nozzle, push the tip of your screwdriver into the slit you cut. Use your screwdriver to pry out the dried chunks of silicone inside of your nozzle. Then, re-tape the nozzle tight with electrical tape to close up the slit and put the tube back into your gun to reuse it. You may get a little resistance at first, but the pressure from the screwdriver should be more than enough to knock the dry silicone out.

Using the Cap and Petroleum Jelly

Rub a pea-sized drop of petroleum jelly inside the silicone cap. Take the tube out of the caulk gun and set it down upright with the nozzle pointing up. Wipe the nozzle down with a rag to remove any silicone. Then, grab the cap that came with your tube and fill the inside of that cap with petroleum jelly. This will keep moisture from sneaking inside of the tube when you put the cap on. This is your best bet if your silicone tube came with a cap. Your silicone should stay usable all the way up to the expiration date. However, if you lost the cap or your tube didn’t come with one, you can’t really use this method. If you simply put the cap on top of the nozzle and leave it, the silicone is going to cure to the cap. These caps aren’t airtight, so your tube won’t be reusable.

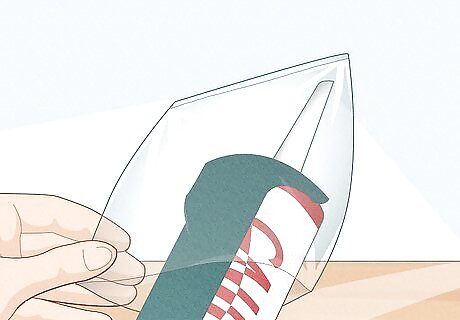

Slide the cap on top of the nozzle. Put the cap on the nozzle the same way it came with the tube. Push it down and let any excess petroleum jelly squeeze out from the bottom. Once you’ve pushed the cap all the way down, use your finger or a rag to wipe away any excess petroleum jelly that’s sticking to the uncapped portion of the nozzle.

Use electrical tape to secure the cap to the nozzle. Grab a roll of electrical tape and start wrapping the tape around the base of the nozzle. Work your way up in a series of concentric layers until you get to the tip. Carefully wrap the tip up along with the rest of the nozzle without lifting it off of the opening. Once the tape fully covers the cap, you can set the tube aside for storage. You could try to use masking tape here, but it may not stick to the tip very well if there’s any residue from the petroleum jelly on the plastic.

Remove the tape and cap to reuse the silicone. When you want to use the tube again, peel off the electrical tape. The cap should pop right off. Grab a rag and wipe the excess petroleum jelly off of the nozzle. Put it back in your caulk gun and you should be ready to go. If the silicone won’t come out, grab a nail or thumbtack that’s thinner than the opening on the nozzle and repeatedly push it into the opening to break the dry silicone up.

Covering the Nozzle with Plastic

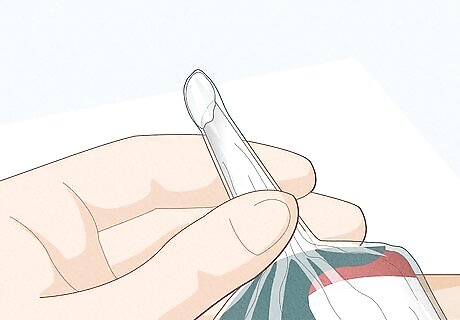

Slide the plastic bag over the tip of your silicone tube’s nozzle. Do not take the silicone tube out of the caulk gun. Wipe it clean with a rag and grab a basic plastic bag. Wrap the bag around the nozzle and let the excess plastic stick out at the sides. This option tends to work well, although your nozzle may dry quickly if you don’t get enough air out of the bag before you seal it. You can also use a sheet of plastic wrap if you don’t have a plastic bag laying around. It’s the same process either way.

Push the air out of the bag while leaving a small gap for the silicone. Keep readjusting the bag and squeezing the tip to push the air out through the base of the nozzle, taking care not to puncture the bag. Leave a small pocket of space between the tip and the plastic bag. Once you’ve got a small gap built up and the excess air is out, use your non-dominant hand to pinch the bag around the center of the nozzle.

Squeeze the caulk gun to drive to fill the tip up with silicone. Give the handle a few gentle pulls to slowly drive some of the silicone out of the tip. Keep your non-dominant hand around the nozzle to keep it from leaking out and fill the small pocket between the bag and the tip up with silicone. Silicone will keep pushing out of the nozzle if you maintain any pressure, so unlock the hook at the end of the caulk gun to completely relieve the pressure once you’ve got enough silicone in the bag. So long as the gap between the nozzle and the plastic bag is totally filled with silicone, you’re good to go.

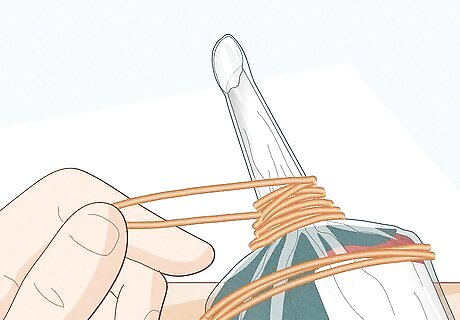

Secure the bag to the nozzle with a few rubber bands. Keep your non-dominant hand pinched around the nozzle and the bag. Wrap a few rubber bands around the middle of the nozzle and the bag a few times to secure it. The silicone that’s sticking out of your nozzle will dry out in a few days and block the opening to the tube. This will keep the silicone inside of your tube from drying out. Unhook the caulk gun or take the tube out of the gun when you’re done. Be sure to store your caulk tube sideways once the bag is tied off. If you store it at an angle, more silicone may leak out of the tip, or some silicone from the bag may drip inside of the tube and speed up the drying process.

Remove the bag and peel off the dried silicone to reuse it. Once you’re ready to reuse the silicone, take the rubber bands off and remove the plastic bag (it may stick a bit to the silicone). Use your hands to peel off the ball of dried-out silicone from the tip of the nozzle. Reload your silicone in the caulk gun and get to work! If it’s still a little soft and malleable, it’s a good sign that your silicone is ready to go. If the silicone at the tip is totally dried out, you may need to recut the nozzle with a utility knife to make a bigger opening.

Plugging the Nozzle with a Nail

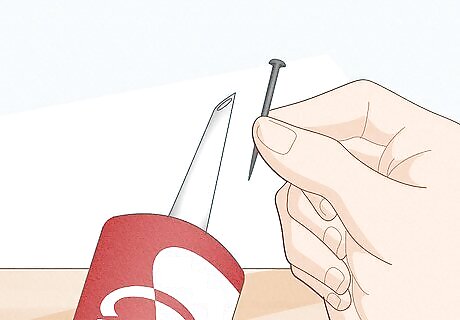

Choose a nail that's just a hair thicker than the opening at the end of the silicone tube. You can use a screw instead of a nail if you prefer. You’re going to fill in the nozzle with this nail to plug the opening. The silicone may dry out around the nail, but you’ll remove it with a bit of force to clear the blockage. This doesn’t always work if you cut the tip of your tube off at a sharp angle since some air can get into the tube through a gap. You can cut the tip straight off before using the tube to make this work better, although you’ll sacrifice some accuracy if you’re sealing any corners if you do this. This is probably the most popular method among folks in construction, but they tend to go through tubes of caulk fairly quickly. The nail or screw can get stuck to the silicone and it can be a big of a pain to get it out if you store the caulk for more than a few days.

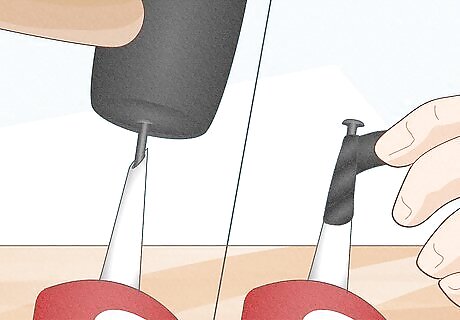

Slide the nail into the opening at the end of the nozzle. Wipe the nozzle clean with a rag. Then, hold the pointy tip of the nail or screw over the opening of the nozzle and push it in. Slide it in a few millimeters until the tapered portion of the screw or nail catches on the rim of the nozzle. If the nail goes in all the way without any resistance whatsoever, it means that your nail is too small. Grab a bigger nail and repeat this process.

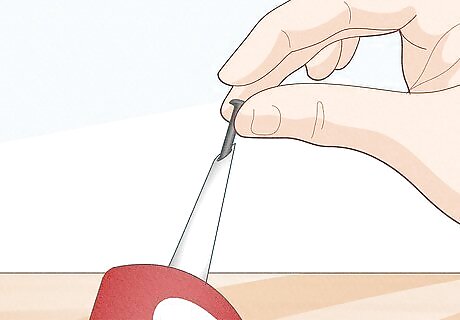

Push or tap the nail in as far as it will go and tape it up. If there’s a bit of give, just physically push the nail all the way in. Alternatively, you can gently tap the back of the nail with a small rubber mallet, or flip the tube upside down and push the head of the nail into a flat surface to force it in. Push it down all the way so that the head of the nail is resting against the nozzle. Put a strip of duct tape or electrical tape around the tip to keep air from sneaking in. If you just can’t force the nail in and you’ve used your tube more than once already, it’s a sign that it has already started to dry out. You can try a different method here, but your silicone may not be long for this world.

Remove the nail or screw with a bit of force to reuse the silicone. To reuse the silicone, remove the tape and grab the head of the nail or screw. Brace the tube with your non-dominant hand and pull the nail out. If you need to use more force, try tugging the nail out with some channel locks or pliers and rip it out carefully. Once it’s out, put the tube in your gun and squeeze out any dried-out chunks to get the silicone flowing again. If you get the screw or nail out but you can’t squeeze any new silicone out, some of it has dried inside of the nozzle and it’s blocking fresh silicone from coming out. Grab a nail that’s thinner than your nozzle and poke it inside of the tube repeatedly to break the blockage up. Use your caulk before its expiration date. If it sits on the shelf for too long, you won’t be able to get the nail or screw out. If the screw or nail won’t budge, it’s time for a new tube of silicone.

Comments

0 comment