views

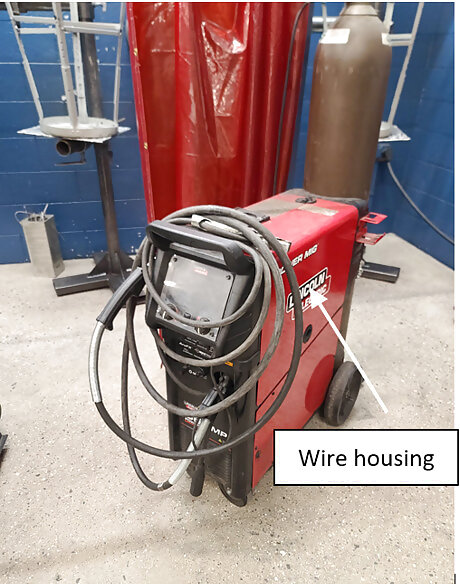

Identify the welder and the location of the wire feed housing.

Turn the machine on and take the wire feed lead and make sure it is unspooled and unkinked in a (mostly) straight position so that the wire can feed freely.

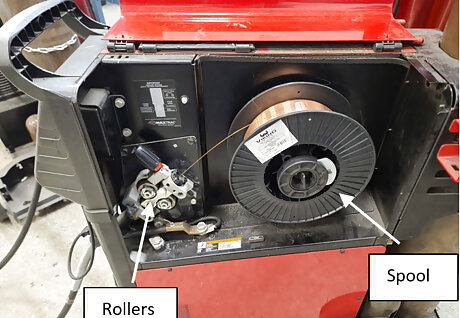

Open the wire feed housing and locate the spool and rollers.

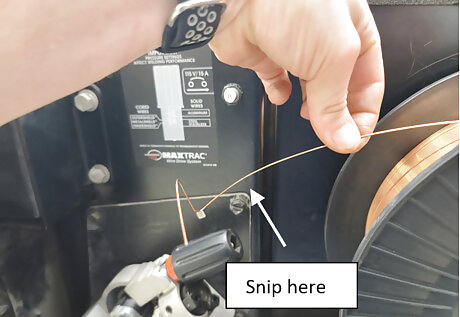

At the MIG Gun end, remove the gas nozzle and contact tip and snip a ½” inch section of the wire off the end. This removes any deformed/melted/belt/balled up wire so it can be pulled back through the wire housing much easier.

Unlatch the tensioner for the rollers and move the roller out of the way so the wire can move freely.

Identify the drive rollers and the latches that hold them in place. Unlatch them and remove the drive rollers. Swap/replace the correct size drive rolls with the correct size drive rolls.

Manually respool the wire onto the spool as to not waste any wire. Remove the spool clasp and then the spool.

Replace the spool of wire with the desired new spool.

Untie the new spool wire and hold the wire closest to the spool and snip off the bent wire on the other side of your hand.

Carefully insert and guide the wire through the feed housing.

Put the drive rolls back into the original position and reset the tensioner (change tension if necessary by twisting the knob).

Ensure your shielding gas is off as not to waste the gas while feeding the wire through the MIG gun lead. If using Gasless Flux, skip this step.

Turn up the wire speed and pull the trigger on the gun to automatically feed the wire.

Remove the gas lens if necessary so wire can feed though unhindered.

Once the wire has fed all the way through, replace the contact tip with correct size tip and gas nozzle.

Set the correct settings for the desired weld process. Turn shielding gas back on and start welding.

Comments

0 comment