views

- Wait for the spray foam to harden and completely cure for 12–24 hours before you cut it.

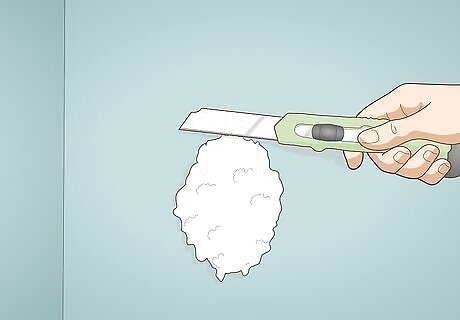

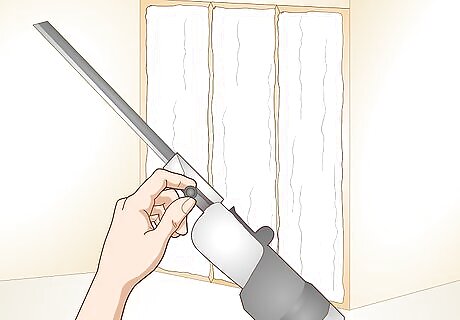

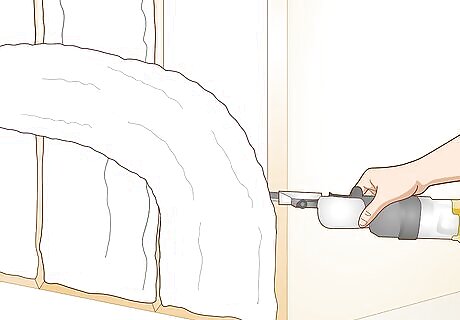

- Use a utility knife, serrated bread knife, or foam saw to trim small pieces of foam. Hold the blade flush against the wall and saw back-and-forth through the foam.

- Cut large pieces of expansion foam insulation with an electric foam saw. Hold the blade flush against the tops of the wall studs and guide it down to slice off the foam.

Trimming Spray Foam Wall Filler

Wait 12–24 hours for the foam to cure before trimming it. Check the curing time on the spray foam’s packaging so you know how long it needs to set, which is usually between 12–24 hours. Leave the foam undisturbed while it expands completely and hardens. Put on a pair of gloves and touch the foam after 12 hours to see if it feels tacky. If the foam is still a little sticky, leave it alone to cure until it has a hard, smooth finish. Avoid cutting the spray foam while it's still curing because you could accidentally pull more foam out from the hole or gap. Uncured spray foam also creates harmful fumes that cause eye, nose, and throat irritation, but it's non-toxic once it's completely dry. Open a window to ventilate the area while the foam is curing. If you can’t open a window and need to be in the same room, wear a respirator, safety glasses and coveralls to protect yourself from irritation.

Hold a utility knife flush against the wall at the top of the foam. Extend the utility knife blade so it’s longer than the section of foam that’s expanded out from the wall. Hold the blade of your knife flat against the wall right above the spray foam to start your cut. Be careful not to press the knife hard against the wall because the blade is usually segmented and could snap apart. If you don’t have a utility knife that’s long enough, try using a long serrated bread knife or a flush-cut foam saw that has a flexible blade instead.

Saw straight through the foam to remove the excess. Move the blade of your knife in quick back-and-forth sawing motions and guide it down through the entire foam piece you’re trimming. Try to keep the blade as flat against the wall as possible so you remove the most amount of foam. Keep cutting through the foam until you reach the bottom, and throw the excess piece you removed in your regular trash. Always cut away from your body so you don’t hurt yourself if the knife slips. If the foam that’s applied in a corner, keep your blade flush against one of the walls so the tip of the blade is in the corner. Cut along the edge of the foam, and then reposition your knife against the other wall to cut the opposite side of the foam.

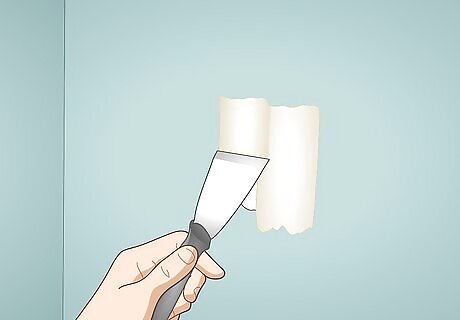

Try using a metal scraper if you can’t cut through the foam easily. Place the blade of your metal scraper against the top edge of the foam so it’s flat against the surface. Apply a firm amount of pressure and use a quick downward thrusting motion to push the scraper through the foam. Keep guiding the scraper through the foam to slice the excess pieces off that extend out from your wall. Metal scrapers work best for rigid foam that’s stuck on studs or too large to cut with your knife. Be careful not to hold the metal scraper perpendicular to the wall surface, or else you may damage or cut into it.

Smooth out the foam with 80- to 120-grit sandpaper or a sanding block. Hold the sandpaper or sanding block against the cut foam. Apply light pressure as you smooth parts of the foam still sticking out with small circular motions. Keep sanding until the foam looks perfectly flush with the surface. Be sure to wipe the surface with a damp cloth to clean up any foam dust before finishing your wall.

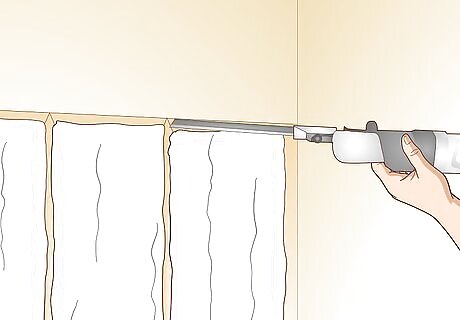

Apply wall filler over the foam to create a perfectly flat surface. Scoop out enough wall filler to completely cover the foam using a putty knife. Spread the wall filler in a thin layer over the foam. Push the filler into any remaining gaps in or around the foam so you have a flat painting surface. Let the wall filler cure for the time listed on the package before sanding it smooth. Wall filler helps prevent the foam texture from showing through the paint.

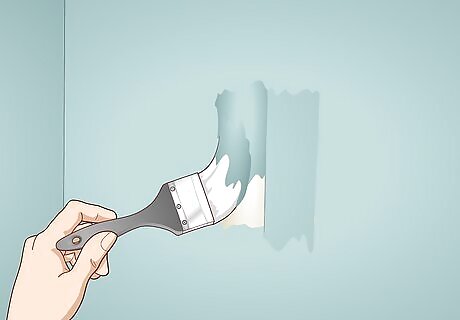

Paint over the foam to finish your wall. Use the same paint color as the rest of the wall to help the spot blend in. Load a foam roller with a thin layer of paint, and apply it over the wall filler. Make sure the spot is completely coated, and let it dry for the amount of time listed on the package. If you can still see the foam or wall filler through the paint, apply a second coat once the first one is dry. Sometimes, fresh paint may dry a different color than the rest of your wall and leave a noticeable mark. If you want to ensure a clean, even finish, then consider repainting the wall.

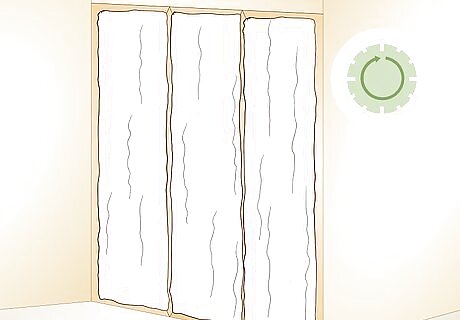

Cutting Expanding Foam Wall Insulation

Give the foam about 24 hours to harden and cure before cutting it. After spraying foam insulation, it expands to fill in any small gaps before it starts to harden. Leave the spray foam alone for at least 24 hours so it has a chance to set. Put on a pair of gloves and test if the foam feels tacky, and if it does, allow it to continue curing until it has a hard, smooth finish. Avoid cutting the foam before it finishes curing because you could damage its insulative seal. Spray foam insulation creates toxic fumes when it’s applied and while it’s curing, and it could cause skin irritation if you touch it. If you need to go back into the room before the foam cures, wear safety goggles, coveralls, and a respirator to stay protected.

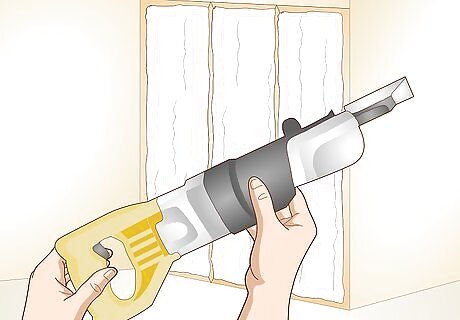

Rent a foam saw from your local hardware or equipment store. Electric foam saws are power tools designed with long, flexible blades that lay flush on wall studs to cut foam that extends past them. Contact a few local hardware or equipment supply stores to see if they offer foam saw rentals. Compare the rates and choose the option that you can best afford. Foam saw blades are usually around 18–27 inches (46–69 cm) long. You may also use a reciprocating saw or angle grinder to cut through the expansion foam as long as you attach a blade specifically made for cutting through foam.

Choose a blade made to cut through the cell structure of the foam. Spray foam insulation either has an open-cell or closed-cell structure, which determines how well it blocks moisture and air. Open-cell foam has small air bubbles inside of it, which helps trap outside air and makes it more flexible. Closed-cell foam fills in the air bubbles to completely block water and air, and it hardens into a more rigid finish. Pick the appropriate saw blade for the foam you used so you don’t cause any damage to your walls or the tool. Avoid using the wrong type of blade on your foam since you could damage the saw or the insulation.

Hold the foam saw’s blade flush against the tops of the wall studs. Start at the top of your wall so the foam comes down easily in a single piece when you cut it. Position the blade perpendicular to the studs so it crosses over 2 of them. Keep the blade as flat against the studs as possible so you make the cleanest cut and remove the most foam. Keep your saw turned off while you’re positioning the blade so you don’t accidentally cut or damage anything.

Guide the saw down the height of the wall to cut the foam. Hold the handles on the side and back of the saw to stabilize it before pulling the trigger to turn it on. Slowly guide the blade down the wall, making sure it stays tightly against the studs. When you reach the bottom of the wall, let go of the trigger to stop the saw and let the foam piece fall down to the floor. You do not need to wear goggles or a ventilator when you’re working with cured foam. Dispose of the foam pieces along with your regular garbage. Wait for the blade to completely stop moving before pulling your saw away from the wall so it doesn’t cut or damage another part of your wall.

Continue trimming the foam between the rest of your studs. Reposition the blade at the top of the wall between the next 2 studs. Pull the trigger and work your way back down toward the floor to remove all of the foam. Keep trimming the foam on your entire wall so the edges are flush with the fronts of the studs. To help with cleanup later on, place a disposable tarp underneath the section of foam you’re cutting. Once you finish trimming the foam and it falls onto the tarp, fold over the corners and throw the whole thing in your trash.

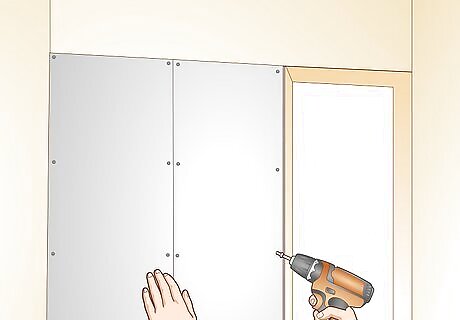

Attach drywall to the studs to cover the foam and finish your wall. Measure the dimensions of the wall and get enough drywall panels to cover the entire surface area. Position your drywall panel flat against the wall, and screw it into the wall studs every 16 inches (41 cm). Cover your entire wall to hide the insulation. Once you have your drywall finished, prime and paint your walls to finish them. Drywall adds another layer of protection against moisture and air so your walls stay even more insulated. If you need to cut drywall to fit into a tight space, score the line with a utility knife and bump it with your knee to snap the pieces apart.

Comments

0 comment