views

Delaying Rubber Hardening

Check rubber objects regularly for hardening. Slowly but surely, any rubber object, be it your car windshield wiper blades or the elastic waistband of your favorite pajama pants, will harden over time. Evidence of white or colored substances on the rubber can be one indication of a chemical reaction taking place. Natural rubber has poor resistance to both ozone and UV light, as well as to petroleum oils. Additionally, temperatures below -60°F (-51°C) or above 220°F (104°C) will degrade it quickly, while temperature extremes in general will facilitate long-term degradation and hardening. Rubber stretches and flexes because it is made up of long, tangled molecule chains that can be straightened out under tension. Degradation of these molecular chains can occur from repeated or excessive tension (think of frayed or over-stretched rubber bands), or by exposure to elements like those noted above.

Examine the rubber for signs of damage. Cracked rubber will remain cracked even when it’s softened. Once cracks form, your only options will be to try out a rubber patch kit or to simply replace the rubber object. There is no miracle cure by this point. One point worth making here is that common softening methods — heat and oils — actually damage the rubber in the process. So, every time you do soften up a stiff rubber gasket or shoe sole, you are also contributing to its eventual demise.

Keep rubber objects clean. There is only so much you can do to keep oxygen, temperature fluctuations, and light away from rubber, but wiping away residue can help keep deteriorating oils from damaging the object. Clean rubber objects with only warm water and a clean cloth when possible. If necessary, use a mild detergent and rinse it away completely. Solvents found in cleaners can degrade or even dissolve rubber. Avoid washing clothes with elastic waistbands more than needed, and don’t use hot water.

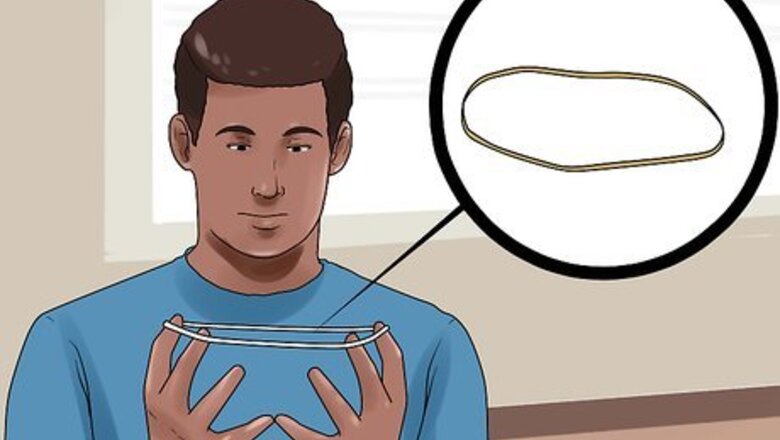

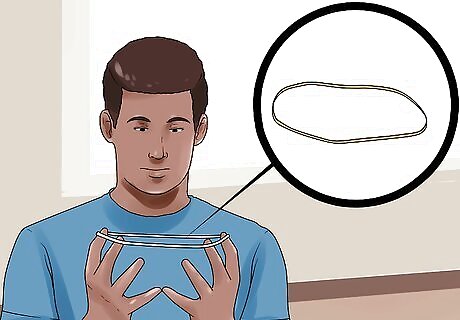

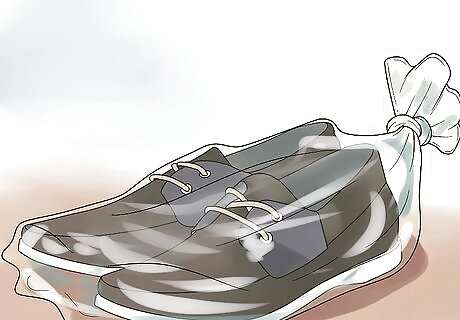

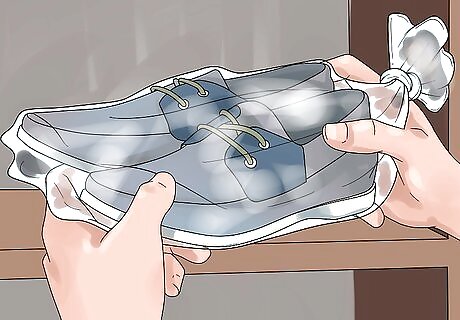

Seal rubber in an airtight container to delay hardening. If possible, remove as much air (and thus oxygen) from the container as you can before sealing it. Placing rubber items in zip-close bags and using a straw to suck out most of the air can noticeably delay the hardening process. If you’ve ever compared rubber bands kept in a plastic bag in your junk drawer from those loose in the drawer, you know the difference it can make. Natural rubber is especially susceptible to oxidization because sulfur is added to the mix when making items like rubber bands. Oxygen reacts with sulfur and essentially removes it from the item, leaving it more brittle.

Place the container in a cool, dry, dark place. The same place you might store apples or potatoes would actually make a decent place to also keep your bagged-up sneakers. 68 to 77°F (20 to 25°C) is a sensible temperature range for storing rubber items, though lower temperatures can also be good. You might even consider keeping tightly sealed rubber items in your refrigerator. The excessive cold and higher humidity of the freezer, however, makes it a less ideal choice.

Softening Rubber With Heat

Choose your preferred heat source. An oven or hair dryer is the most likely choice, although some people espouse placing rubber-soled shoes on a radiator, for instance. Ensure your oven’s heat element can run at a low setting and your blow dryer’s heat element can use a high setting, to get approximately equal temperatures. A clothes dryer placed on its highest heat setting could be another option, especially for sneakers. The temperature range you seek is roughly 200-220°F (93-104°C). Temperatures above this range will likely do more damage than good. Remember to clean rubber objects, ideally with just water, before heating them.

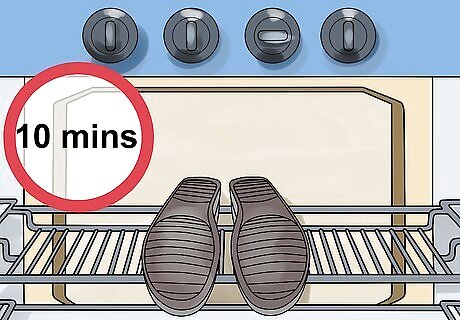

Place the rubber object in an oven on the “warm” setting. In case your oven overheats and melts the rubber, place the item(s) on an oven-safe pan or another container (but one you won’t use for food). If you are heating shoes, make sure the soles are facing up, to reduce the chance of them melting onto the oven rack or pan. Keep the item(s) in the oven for five to 10 minutes. If you happen to have an infrared surface thermometer, you can take the guesswork out of reaching the desired temperature range. Again, be careful about overheating, because high heat will break down rubber, and because cleaning up melted rubber is no one’s idea of fun.

Heat the rubber with a blow dryer, alternatively. For rubber-soled shoes, at least, heating on “high” for seven to ten minutes has been claimed to be successful. Don’t hold the dryer in any one spot, and check the rubber item regularly for signs of melting or other deterioration. Check carefully, however, as the rubber can become very hot. Again, an infrared surface thermometer could prove useful.

Allow the rubber to cool for 10 minutes. Then, try to manipulate it. With luck, the item will remain softer and more flexible even after cooling. Keep in mind, however, that there are many rubber formulations, and some may respond better than others. Also, there is no miracle cure, and some hardened rubber items will simply be too far gone for softening. You are actually damaging the rubber by heating it to soften it, and some items cannot take the beating any longer.

Softening Rubber With a Soak

Remove the rubber part from non-rubber components so that it can be soaked individually. This method is best for industrial or mechanical rubber parts that will be inserted back into an assembly. Unless you have rubber soles that can easily be removed and reattached, this may not be the best method for shoes. The soaking solution may damage or discolor leather or other shoe materials. Remember to clean the item thoroughly first, ideally with just warm water and a clean cloth.

Mix a solution of three parts rubbing alcohol to one part wintergreen oil. Make sure that the amount of the solution is enough to completely cover the rubber item when placed in the container. Although both these liquids can be handled safely in small quantities, it may be best to use tongs or gloves when inserting and removing the rubber object. At very least, you will keep your hands from smelling like wintergreen.

Submerge the rubber item, seal the container, and check regularly for softening. Sealing the container will limit evaporation, which may expose your submerged item. It may take only a few hours to see results, or instead take several days. Be patient and keep checking. After several days, however, you are unlikely to see any additional benefits by keeping the item soaking.

Remove the softened item and wipe it with a clean cloth. Allow the rubber to air dry. Although the rubber will smell strongly of wintergreen, it is best not to use water to wash the substance off. By leaving the leaving the oil in place, the softening process can continue. Of course, remember that the oil residue is also slowly damaging the rubber while softening it, so you’ll have to use your best judgment as to whether it is best to leave it on or rinse it away with water. It is probably best regardless to avoid using harsh detergents.

Comments

0 comment