views

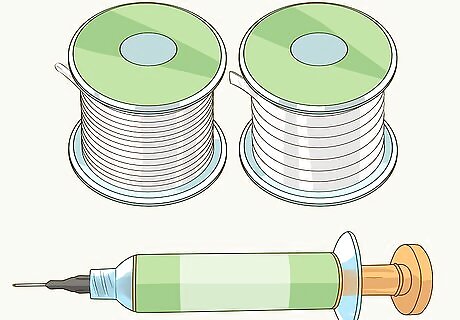

Select extra-easy solder temperament.

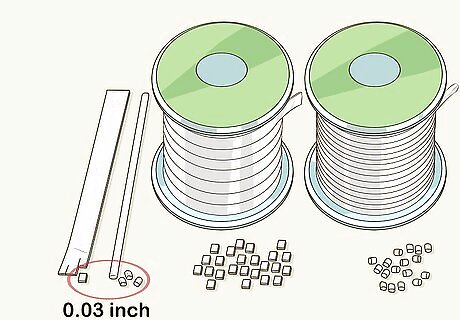

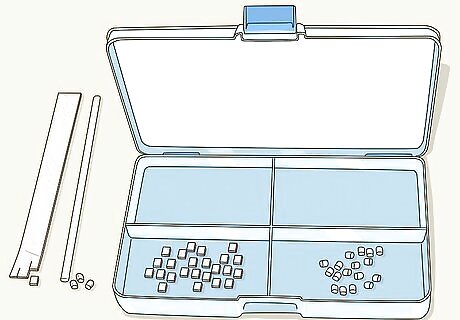

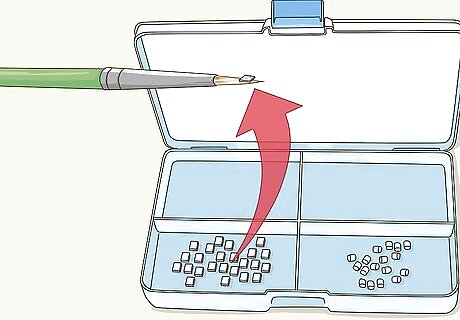

There is only one temperament of solder that requires a lower heat (called low-temperature solder). Jump rings, therefore, do not require a solder that melts at a very high temperature. Cut extra-easy solder into very small chips using tin snips that do not exceed .03 inch (1 mm) squares.

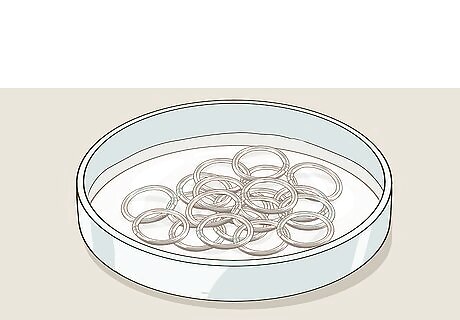

Place all cut solder into a designated container and do not confuse or mix it with other varieties of solder.

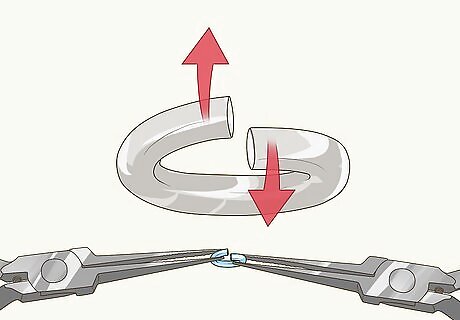

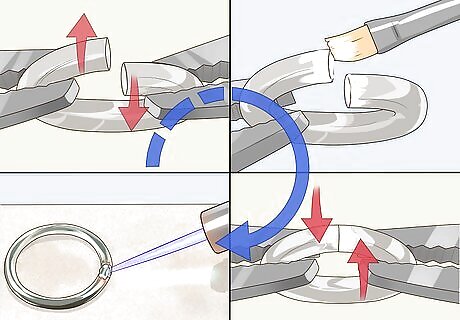

Open the jump ring with a set of pliers using needle-nose pliers if the ring is small.

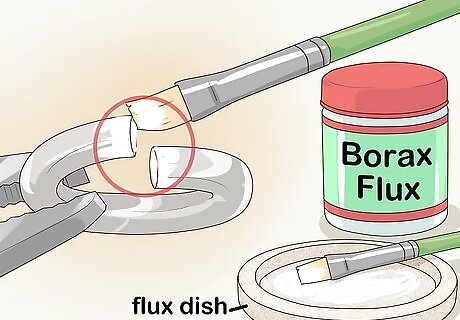

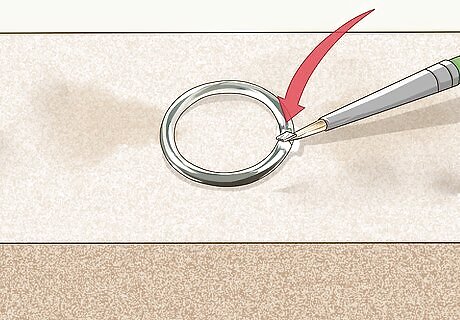

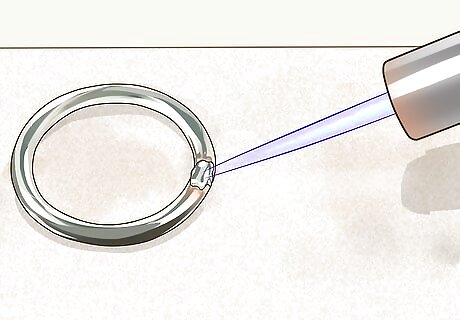

Apply flux to both ends of the opened jump rings with a small, fine paintbrush. Flux is an agent that assists the solder in flowing into the joint. Flux comes in a variety of forms, but one common form is borax.

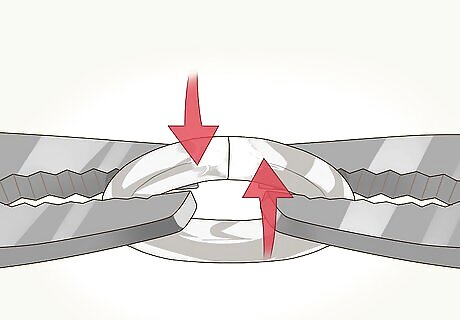

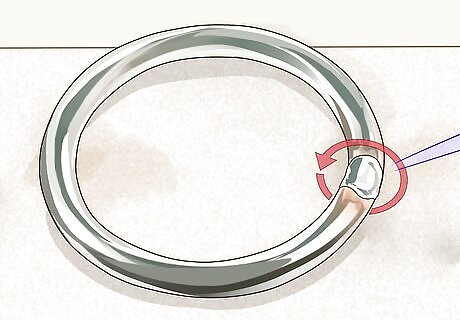

Close the jump ring with the pliers ensuring that the two ends of the jump ring are flush against one another.

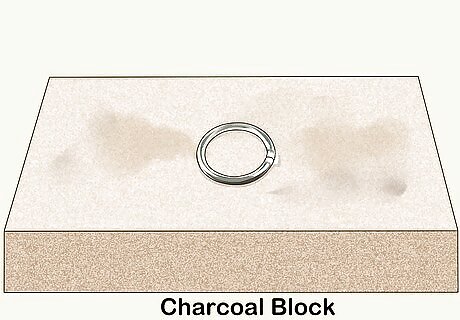

Place your jump ring on a charcoal block. Before soldering jump rings, the joint should be touching the block.

Pick up one extra-easy solder chip with the tip of the small, fine paintbrush.

Place the solder chip on the joint.

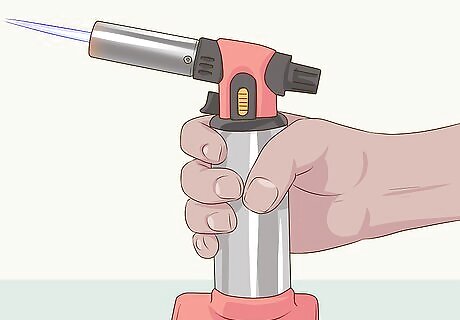

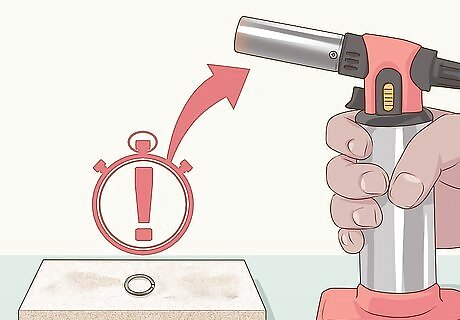

Turn on your soldering torch.

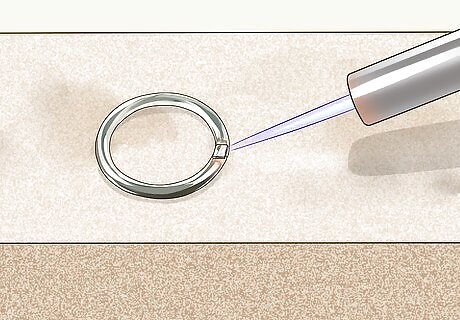

Heat the jump ring as well the charcoal block and do not directly heat the solder. When you solder metal jump rings, the solder will flow to the hottest place.

Watch for the solder to melt. The solder will have a liquid appearance at this stage.

Watch for the solder to flow.

This entire process will happen very quickly. Immediately remove the heat.

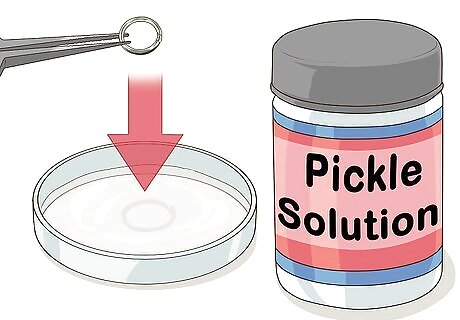

Place the jump ring into a pickle solution. A pickle is a solution that removes a layer of oxidation on the soldered metal.

Wait until you have soldered all jump rings, as they can all be added into the pickle at the same time.

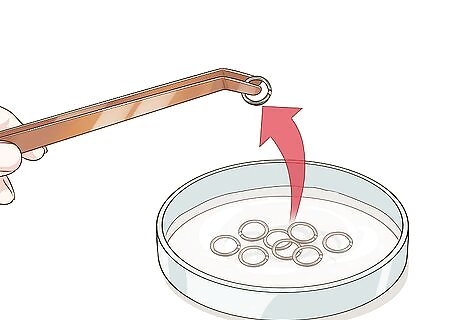

Remove the jump ring(s) from the pickle solution using copper tongs.

Rinse the jump rings with water.

Repeat the process on all jump rings requiring soldering.

Comments

0 comment