views

- Jack up your car and remove the tire with the bent rim. Deflate it (if it’s not flat) and separate the tire from the rim with a prybar.

- Lay the bent rim flat and heat the bend with a blowtorch. Place a piece of wood against the bend and hammer it with a mallet until the bend is gone.

- Reconnect the tire and rim, and test the finished product for air leaks using soap and water. Once you’re sure it’s ready, reattach the tire to your car.

Check whether your wheels are steel or alloy.

Making fixes is easier when you know the material you’re working with. Steel rims are heavier than aluminum alloy and have less variation in their design. While they’re fixable, they’ll never be completely good as new. Aluminum alloy rims are lightweight with a chrome finish, but there’s a greater risk of damaging the wheel while fixing one.Take extra care and work slowly but safely as you proceed! If you’re unsure whether your wheels are steel or alloy, grab a magnet and test it out. If the magnet sticks, it’s steel. If not, you have aluminum alloy wheels. If you have alloy wheels, it’s best to at least consult a professional before moving forward.

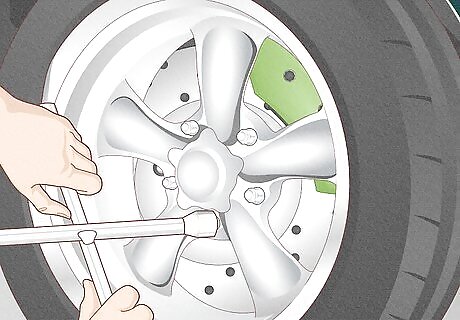

Loosen the lug nuts on the bent wheel.

Loosening the lug nuts now will help you remove the wheel later. Grab a tire iron and loosen all the lug nuts in the wheel, turning each one about a quarter-turn counterclockwise. Don’t remove the lug nuts entirely or leave them extremely loose; just loosen them a little for now. Lug nuts (also called lug bolts) are the fasteners that secure each wheel to the car. Most wheels have 4, 5, or 6 lug nuts, depending on the type of car they’re designed for.

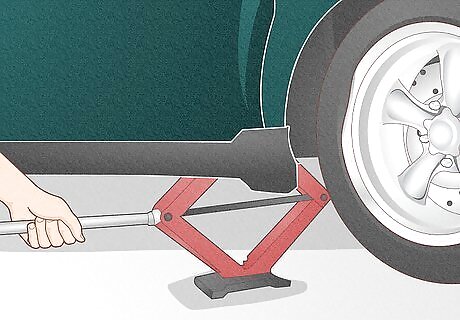

Jack up the side of the car that has a bent rim.

The car jack lifts the car so you can remove and fix the bent wheel. Lift the car by placing your car jack underneath the vehicle and raising it until the tire with the bent rim isn’t touching the ground at all. Ensure the jack rests underneath the car’s frame as it raises to stabilize the car. Park your car on a hard, completely flat surface before jacking it up, and set up bricks or cinder blocks in front of each wheel at the opposite end of the car from where you’re lifting. If you have a flat tire, remember to leave enough space for a fully inflated tire so you can reattach it with ease. Many cars have a designated jack point on each side of the car behind the front wheels and in front of the back wheels. Check your owner’s manual to find the jack point for the wheel you need to fix!

Remove the bent wheel from your car.

Unscrew the lug nuts all the way so you can pull the tire off the car. Finish unscrewing each lug nut with the tire iron until they come off the lug stands. Set aside each lug nut in a small bowl so you don’t lose any since you’ll be reattaching them later! Then, carefully grip the back of the tire and pull it towards you to remove it. With your car jacked up, it’s easier to remove the tire safely. That’s why you wait to finish unscrewing the lug nuts until after the jack is in place.

Deflate your tire if it’s not already flat.

A fully-inflated tire is hard to work with while you make repairs. Sometimes, a bent rim can flatten a tire before you even make repairs. If it’s still inflated, let the air out of your tire by removing the tire’s valve cap and attaching a tire pressure gauge onto the valve. Then, press the tip of a screwdriver onto the metal pin at the center of the valve until the tire is deflated. If your tire isn’t flat, it’s a good idea to consult your local mechanic and get their opinion about the state of your tire before continuing with the fix.

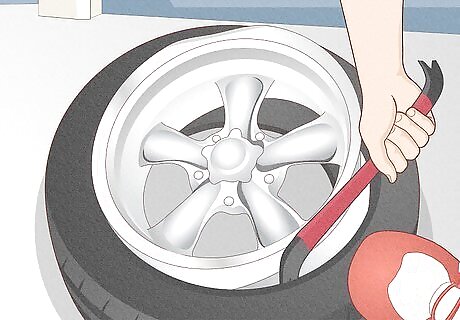

Separate the rim from the tire.

Use a prybar to lift the tire over the top lip of the rim. Since the tire can get in the way of repairing the rim, start on 1 side of the tire and push down on the rubber. Then, slide the prybar underneath the rubber and left it. While holding the tire in place with the prybar, go around the rest of the wheel with a screwdriver, lifting rubber until you can pull the rim out. Before you get to work on the tire, you could ensure you locate all the bends by rolling it. If the tire changes direction suddenly or hops at certain points, that’s where the bend is.

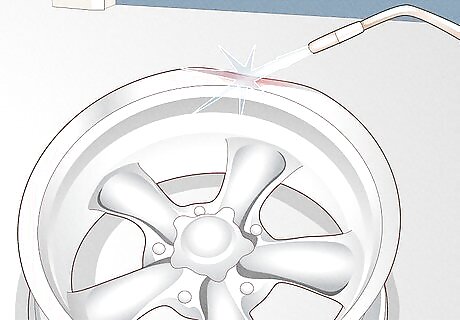

Heat the bent area of the rim with a welding torch.

Heat makes the metal more malleable so that you can fix it easily. First, put on safety goggles and protective gloves. Turn on a welding torch (also called a blowtorch) and heat the bent side of the rim, concentrating on a single portion of the bend for about 2 minutes. Make sure you know how to use the blowtorch before doing this portion of the process. If the bend is particularly deep or large, you might have to heat it for longer than 2 minutes. Double-check that the welding torch is turned off before you put it down to fix the bent rim.

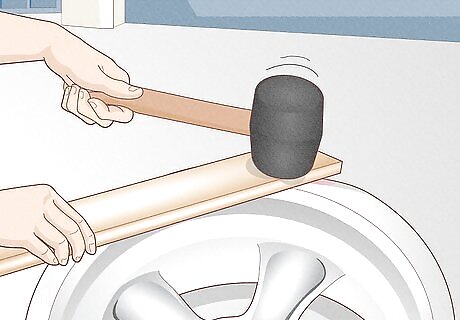

Set a piece of wood against the bend.

The wood deflects the mallet, so it doesn’t mark up the rim. Grab a piece of wood and set it against the bend, so you’re actually hammering on the wood, not the rim. Hold the wood in place for the duration of the repairs, and use it to reshape the bent in your wheel more safely. Just remember to be careful of the fingers holding that wood while using the mallet. The most effective piece of wood should curve like your wheel. If you can’t find that, then any small wood block can still be good protection.

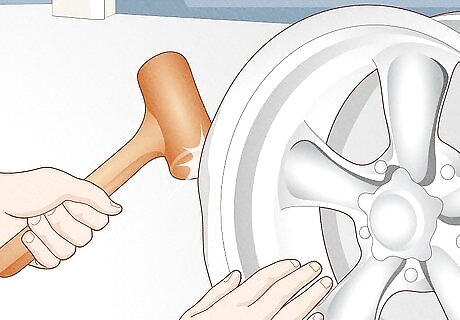

Hammer the bent rim into its original shape.

A sturdy hammer can reshape the metal on the tire’s rim. Grab a 4 pounds (1.8 kg) dead blow hammer and pound out the dent, applying a medium amount of pressure with each strike until the rim straightens. If the rim’s material isn’t responsive enough to fully straighten out before cooling, repeat the process of heating the dent and then hammering it until it’s back in place. If the rim won’t even out while using the wood block, it’s okay to remove the wood and hammer the rim directly. Hitting the rim too hard directly can cause it to crack, so keep the force of your blows steady and don’t apply extra pressure even if the fix takes some extra time.

Reattach the tire to the rim.

Wait until the rim is completely cool before reattaching the tire. Get the tire back on the fixed rim by applying metal lubricant liberally to both the tire and rim. Lay the rim flat on the ground and placing the tire on top of it. Press the upper lip of the tire down onto the rim 1 side at a time, and use the prybar to force the tire’s lip over the rest of the rim. When you’re done mounting the tire, inflate it with an air compressor. Ensure both tire beads are past the rim’s lip before attaching the compressor to the tire’s valve stem. Use the pressure gauge once again while inflating the tire to ensure it reaches its proper PSI (pound-force per square inch).

Test the tire for air leaks.

Separating the tire and rim can cause air leaks, which cause a flat tire. Spray some water across the space where the rim and tire meet, then examine it carefully for bubbles that might be forming. If you see bubbles, it means you likely have a leaky rim, with the air coming from between the rim and the tire. If you do find a leak, bring the tire to a professional so they can examine (and possibly fix) it.

Replace the tire on your vehicle.

Screw each lug nut back into place before tightening them. Roll the finished tire back to your car, align the holes in the tire rim with the lug nut studs, and slide it onto the vehicle. Then, with your tire iron, screw each lug nut back into place; start with the one on the bottom and work on lug nuts that are opposite one another (saving the top for last) until the rim is pulled evenly against the studs. Tighten the right and left lug nuts after you screw each one into place. Afterward, lower the car jack until your car is flat on the ground and remove the jack entirely. Tighten every lug nut on the wheel once more, and your car is ready to be driven!

Comments

0 comment